Assessment of Soil Moisture Content Measurement Methods: Conventional Laboratory Oven versus Halogen Moisture Analyzer

Abstract

Moisture content is a critical factor that affects the engineering behavior of soils, especially cohesive soils. Therefore, the monitoring and determination of the water content is an essential task in an experimental study in the field of geotechnical engineering. There are different techniques and standards to measure soil water content. ASTM D2216 is a laboratory standard test method for the determination of water content of the soil widely used in the United States as well as many other places around the world. The complete drying process of a soil sample in a conventional laboratory oven for twenty-four hours is the core of this standard. However, the process is rather time-consuming. On the other hand, halogen moisture analyzers reduce the time required to determine the soil water content significantly. This study focuses on assessing the applicability and precision of the halogen moisture analyzers versus the conventional laboratory ovens to obtain the soil moisture content. For this purpose, different soil types, cohesive and granular, at different moisture contents were tested using both methods. The conventional measurement method of soil moisture content according to ASTM D2216 as the reference. The results obtained by the halogen moisture analyzer were compared with the results obtained by the conventional method. The results were in good agreement, and the comparison showed that the halogen moisture analyzer is a fast, simple, and relatively inexpensive alternative method to determine the soil moisture content. Consequently, a halogen moisture analyzer as an energy-efficient device can measure soil moisture content with a reliable and relatively automated process minimizing user errors.

Keywords

Moisture content, Drying oven, Halogen moisture analyzer, ASTM D2216

Introduction

A conventional laboratory oven has been strongly used for a variety of applications in the industry. It is crucial equipment for removing the moisture in many types of soils and other material types. Their principle of gravity convection and drying process allows this apparatus to be considered as an essential item for drying processes.

Many important engineering properties of the soil, especially cohesive soils, are a function of soil water content. Estimation of water content, liquid limit and plastic limit of soil are crucial steps to predict the engineering behavior of the soil. The water (or moisture) content is defined as the ratio of the mass of the pore water to the mass of soil Solids particles. Solid particles referred to material that is not readily soluble in water. ASTM D2216 presents a simple method to measure the soil water content by using a conventional laboratory oven and has been used since long time ago and still is considered as essential equipment. This standard is widely used in practice in the United States as well as in many other countries around the world.

Consequently, the definition of water content and the standard procedure to determine the soil water content depends on the type of different materials or chemicals presented in the soil. For instance, ASTM D2974 presents the test methods for moisture, ash, and organic matter of peat and other organic soils. ASTM D4542 defines a treatment method to squeeze pore water from fine-grained soils.

Precise drying of the soil specimen in a vented, thermostatically-controlled with a uniform temperature of 110℃ ± 5℃ throughout the drying chamber [1] is the core of ASTM D2216. The drying process is slow and time-consuming. Drying time depends on several factors, including the initial water content, soil type, the specifications of the oven, and the specimen size. Nevertheless, two hours is a minimum period to dry specimen tests [1].

International Organization of Standardization (ISO) and British Standard Institution (BSI) recommend somehow similar procedures to ASTM D2216 to determine the soil water content by using a drying oven (ISO 17892-1:2014). Additionally, there are many different direct and indirect methods to measure soil water content such as gravimetric method, neutron scattering, tensiometer, electric resistance methods, signal processing, ground penetration radar (GPR), capacitance technique, and the heat-pulse method.

There are numerous direct and indirect techniques to measure soil water content. The standard method (gravimetric method) is a basic calibration method, and it is used to compare different methods with one another. It is necessary to note that the results from different methods should be comparable [2]. In 1970, Reynolds mentioned that in most field examinations, samples of 50 to 100 g of soil are enough. Moreover, the drying time for larger samples of 500 g increases. His study aimed to examine in detail the equipment and methodological problems of the gravimetric method used to estimate soil moisture [3].

Neutron scattering is a method that measures soil hydrogen content to calculate its moisture content. In this way, the moisture content is measured by counting the number of slow neutrons per unit of time [4]. Gee and Dodson, in 1981, used the simple microwave drying procedure with considering a standard drying time to determine soil water content. The result of their investigation showed that the microwave method is helpful and in significant agreement with the standard electric oven method [5].

The synthesis method and decomposition analysis are the two signal processing methods to measure soil moisture Content [6]. Nowadays, many techniques are used to determine the water content of the soil; however, they are expensive and require lots of time. A novel and well-defined idea is the use of the geophysical method GPR. It can catch a subsurface picture through pulses that can provide a modulated frequency based on the moisture content [7]. The capacitance technique is another way to measure this soil parameter. The primary purpose of this method is to measure the dielectric constant of the soil [8]. The Heat-Pulse method can also be considered as an optimal and low-cost method to calculate the moisture content in soils. The objective of this method is to dissipate an applied heat pulse on the soil. It is based on the theory of radial heat conduction, where the temperature changes with the increment of the time in a circular extension [9]. The results were compared and correlated with the oven-dry technique providing a very close prediction [10].

Over the years, the measurement of the water content of the soil has been done by using a conventional oven in soil mechanics laboratories. It has been a piece of essential equipment for drying soil samples, but with some limitations such as long drying time and portability. The halogen moisture analyzer (HMA) is a novel technique to determine the water content for a wide range of materials. However, limited information can be found for analyzing moisture content in soils by using a halogen moisture analyzer as it is a relatively new device in soil mechanics laboratories.

The moisture content is a critical factor that affects the engineering soil properties. Therefore, monitoring and accurate determination of moisture content are essential. The Halogen moisture analyzer (HMA) is a fast determination technique that can be used to estimate the water content of the soil. It should be mentioned that the results of this quick method should be comparable with the drying oven method. The HMA is a new standard test in some industries, such as plastics, but there is not any available standard about the HMA method for measuring soil moisture content. ASTM is a reference method to estimate moisture content by the oven. If the results obtained by the drying oven method and the halogen moisture analyzer are comparable, it is possible to use the halogen moisture analyzer instead of the drying oven method.

Regarding this equipment, the Halogen moisture analyzer is an instrument mainly used in the pharmaceutical, plastic, and food industries to calculate the water content in some products. A practical and accurate method to estimate this parameter is the thermo gravimetric technique. The principle of this sophisticated machine involves a halogen radiator which dries the sample while a balance is capturing and recording the decrease in weight. After analyzing the procedure, the loss in weight that the sample experience can be understood as the moisture content of the specific sample. This compact equipment can perform many functions in a short time, allowing fast and effective data collection leading to a quick laboratory operation and sample understanding.

The halogen moisture analyzer is an innovative, fast, and highly accurate technique to determine the moisture content of a wide variety of materials. This investigation is the first study that quantitative analysis is performed to investigate the soil's moisture content by a halogen moisture analyzer. The loss on drying (LOD) is a reference method to estimate moisture content by using the drying oven. Reliability and testing of several samples at the same time are some of the advantages of this method. LOD needs only a drying oven and typically an analytical balance. However, this method is relatively slow, and it takes too long to obtain moisture content. HMA is faster than LOD, and it usually takes 15 to 30 minutes to measure the moisture content. Besides, HMA is an easy technique, and it is well adapted for different environments.

This research wants to show the magnificent functions that the HMA can provide to the soil material industry and the opportunities this small equipment can give in terms of moisture content determination. This study provides substantial results on determining the water content on two different soil types in small amounts in a short time. The HMA provides a practical guide and documentation on how to dry samples using a continuous measurement method that uninterruptedly calculates the mass, which provides more accurate values. As future recommendations, a complete and standard guide in compliance with ASTM could be developed to determine moisture content in soil material by using the halogen moisture analyzer. This technique could be included in the ASTM standard and performed by any industry or individual.

Materials and Methods

Soil

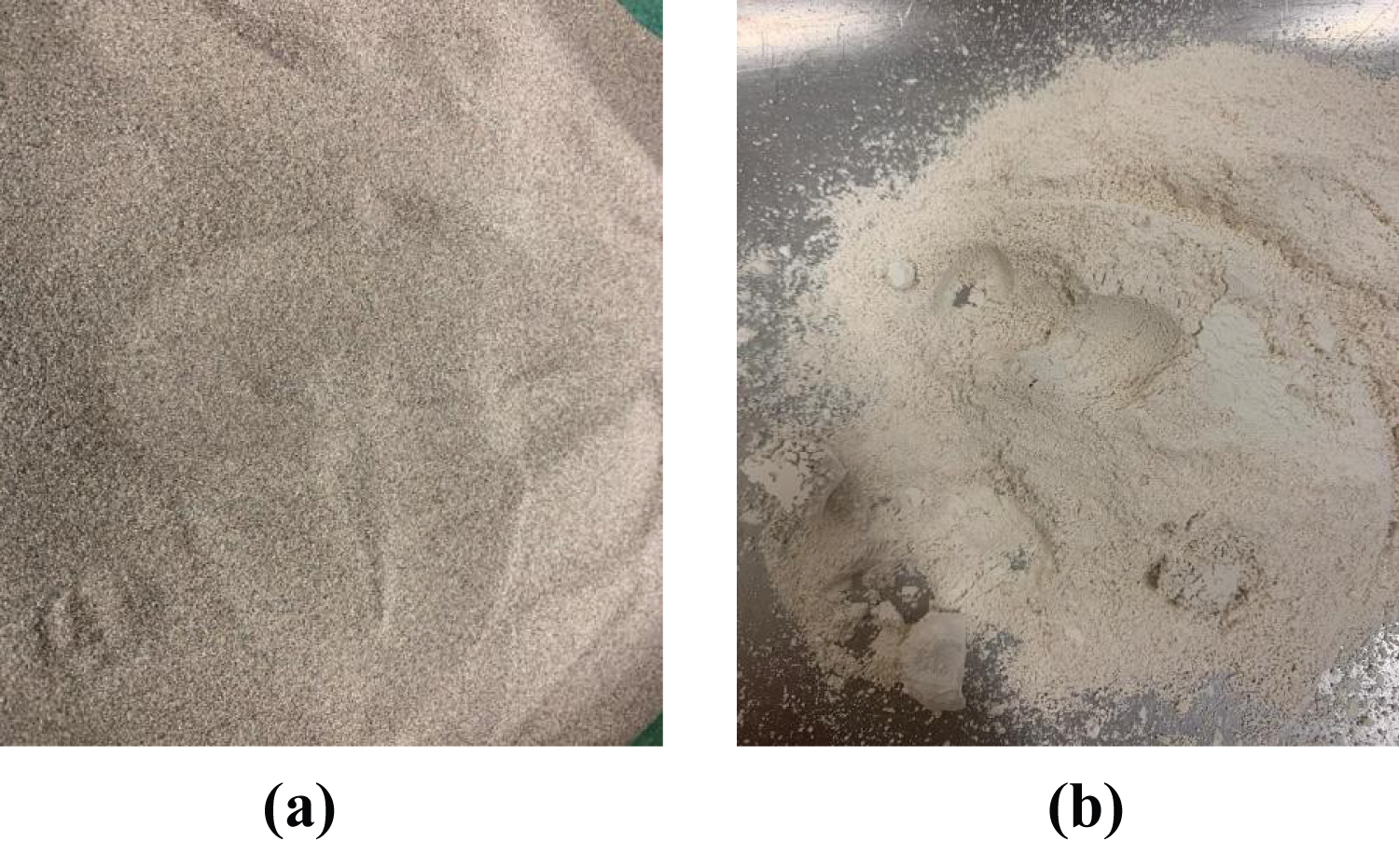

For this investigation, oven-dried pure silica (Gs = 2.65) sand and Kaolin clay (Gs = 2.58) specimens were utilized for laboratory testing. Sand particles range in diameter larger than 0.149 mm (retained on sieve # 100), and fine particles range in diameter less than 0.60 mm (passing sieve # 30). The moisture content was determined for all specimens by using the oven-dry method and the halogen moisture analyzer (Figure 1).

Water

For this study, distilled water matches the type II water defied by ASTM D1193-91 (a resistivity more than 1 MΩ - cm, a conductivity less than 1 μS/cm, and less than 50 ppb of Total Organic Carbons (TOC)) provided by the chemistry department was used [11].

Oven-dry method procedure

In this study, two different processes were carried out. The first approach is characterized by the uses of one soil type and the different amounts of water. In the second approach, specimens made of clay mixed with different percentage of sand (by dry weight of the soil) ranging from 10% to 100% with an increment of 10% were made and mixed thoroughly with 100% of distilled water (by dry weight of the soil) assigned to each container.

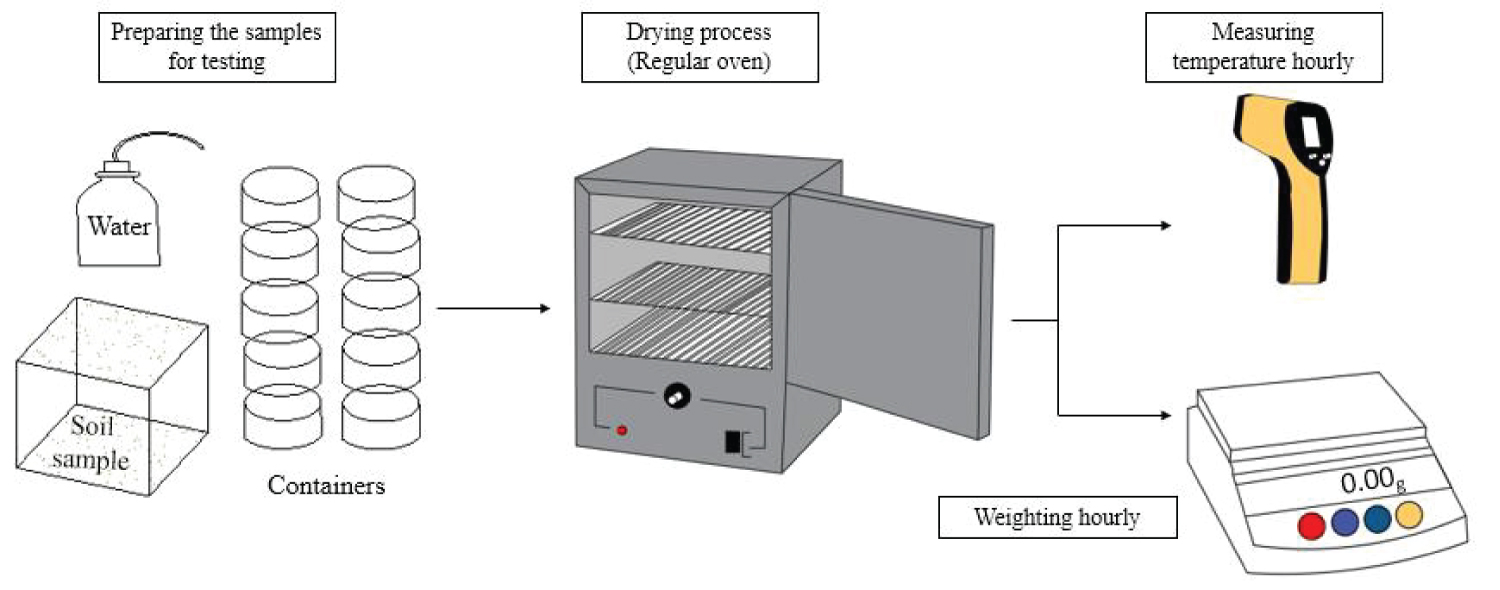

The different percentages of distilled water by dry weight of the soil ranging from 10% to 100% with an increment of 10% were added to the sand and clay samples to perform the moisture content analysis. Ten containers were filled with 30 g of the soil sample mixed with different percentages of distilled water. The procedure and parameters to determine the moisture content of the soil were based on the specifications of the ASTM standard D2216-19. Figure 2 shows the scheme of the process that was developed in this study.

The drying oven used in this study was a gravity convection oven, and the average air pressure at the test location was about 30 inches of mercury units. The temperature stability of the oven is ± 3 ℃. The temperature of the drying oven was maintained at 110℃ ± 5℃ during the complete drying process. Before placing the specimens in the oven, each container was weighed before and after adding the soil sample and distilled water. The specimens in the oven weighed on an hourly basis for 24 hours. The balance used for weighting the samples has a precision of 0.01 gr.

Another parameter that was estimated hourly was the temperature of soil by using a non-contact infrared thermometer to monitor the soil temperature during the drying process. The measurements were done before hourly weighing to have a more accurate temperature reading by minimizing the exposure of the specimens to the cooler air of the lab. The specimens were taken out of the oven after a period of 24 h when no significant weight loss was observed, and the water content was determined according to ASTM D2216-19. The results were used as a reference for the results of the other

Method (halogen moisture analyzer).

Halogen moisture analyzer

Halogen moisture analyzers have been used to determine the moisture content of different materials. However, to the best of the authors' knowledge, this is the first study that quantitative analysis is done to compare the moisture content of the soil obtained by a conventional method with the one determined by a halogen moisture analyzer.

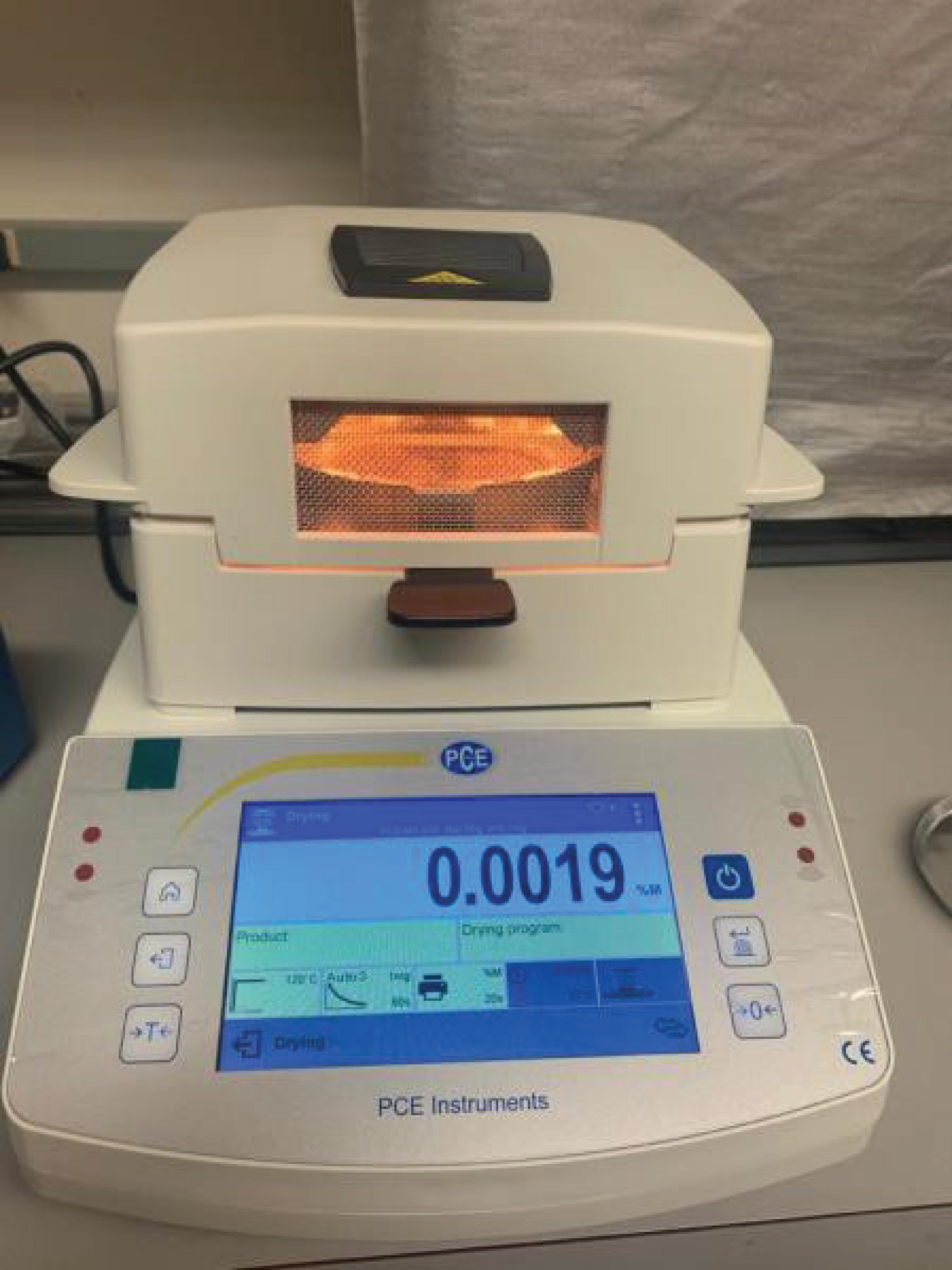

A typical halogen moisture analyzer is equipped with a halogen lamp technology that heats the material to dry it quickly. Figure 3 shows the halogen moisture analyzer used in this study. It has a user-friendly interface displaying all the essential information during the drying process on the screen. The procedure starts with adding the soil sample with a specific percentage of distilled water in a particular container and place it in the device. The equipment is fully automatic, and the opening and closing of the specimen cell take place on the moisture analyzer without contact. The halogen moisture analyzer performs by determining the initial weight of the sample. The internal halogen dryer heated the sample quickly until causing water content to vaporize. The drying time is shorter than a conventional oven, and once the drying procedure finishes, it automatically opens the cap, and a record of the moisture content is displayed on the screen monitor. The sample's maximum weight in the halogen moisture analyzer is 50 g, and its weighting precision is 0.1 mg. The drying temperature for the halogen moisture analyzer can be increased up to 160 ℃. A temperature of 110 ℃ ± 5 ℃ was maintained for all the tests. The maximum sample mass in the moisture analyzer is limited to 50 g for the halogen moisture analyzer used in this research. For this study, the mass of the dry soil was limited to 30 g for sand and 20 g for clay. Due to the equipment limitation, only 10% to 100% of distilled water with 10% increment were added to samples to perform the test. The detailed information is stored on the moisture analyzer's internal memory and can be exported to a computer for further analysis.

Results and Discussion

Tests were performed using several schemes: first, the same soil material with different water content was developed, and second, the same water content using different portions of soils. Table 1 shows definition for the specimen names.

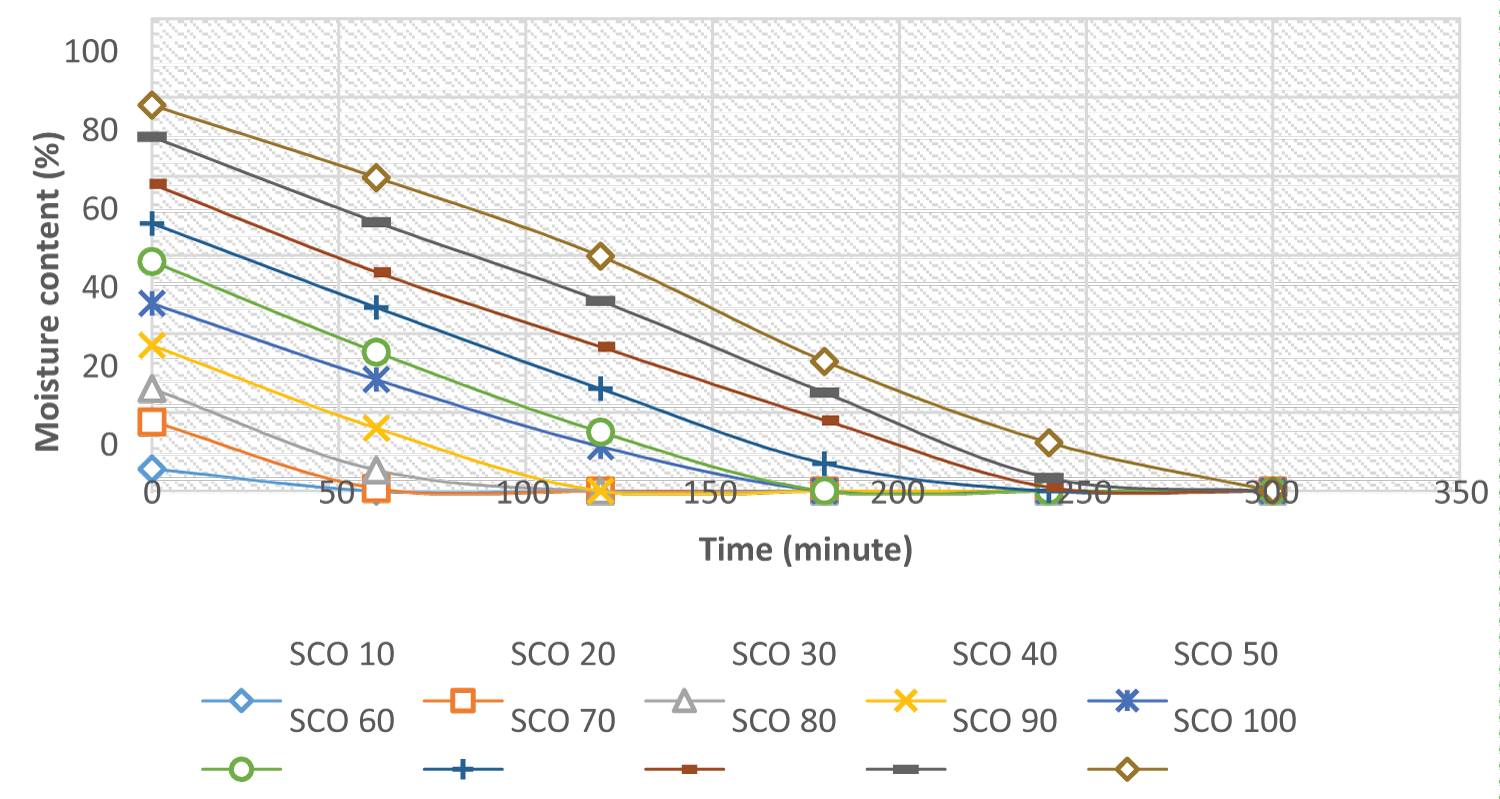

The primary goal of this research is to compare the performance and reliability of a halogen moisture analyzer results with the results of a conventional lab oven. The results show that drying time and oven temperature have such a significant effect on the soil moisture content. Figure 4 shows the moisture content versus time for the 10 sand specimens (SCO stands for Sand specimen in the Conventional Oven. The number after SCO refers to water added to the specimen as a percentage of the dry sand mass).

As it is shown in Figure 4, the soil moisture content is reduced with time until the specimen weight remains constant. The results of the experiments demonstrate that the required time to complete the moisture content test by using the regular oven varies. It depends on several different factors, including oven temperature, initial water content, and type of soil, assuming that the temperature of the oven is constant.

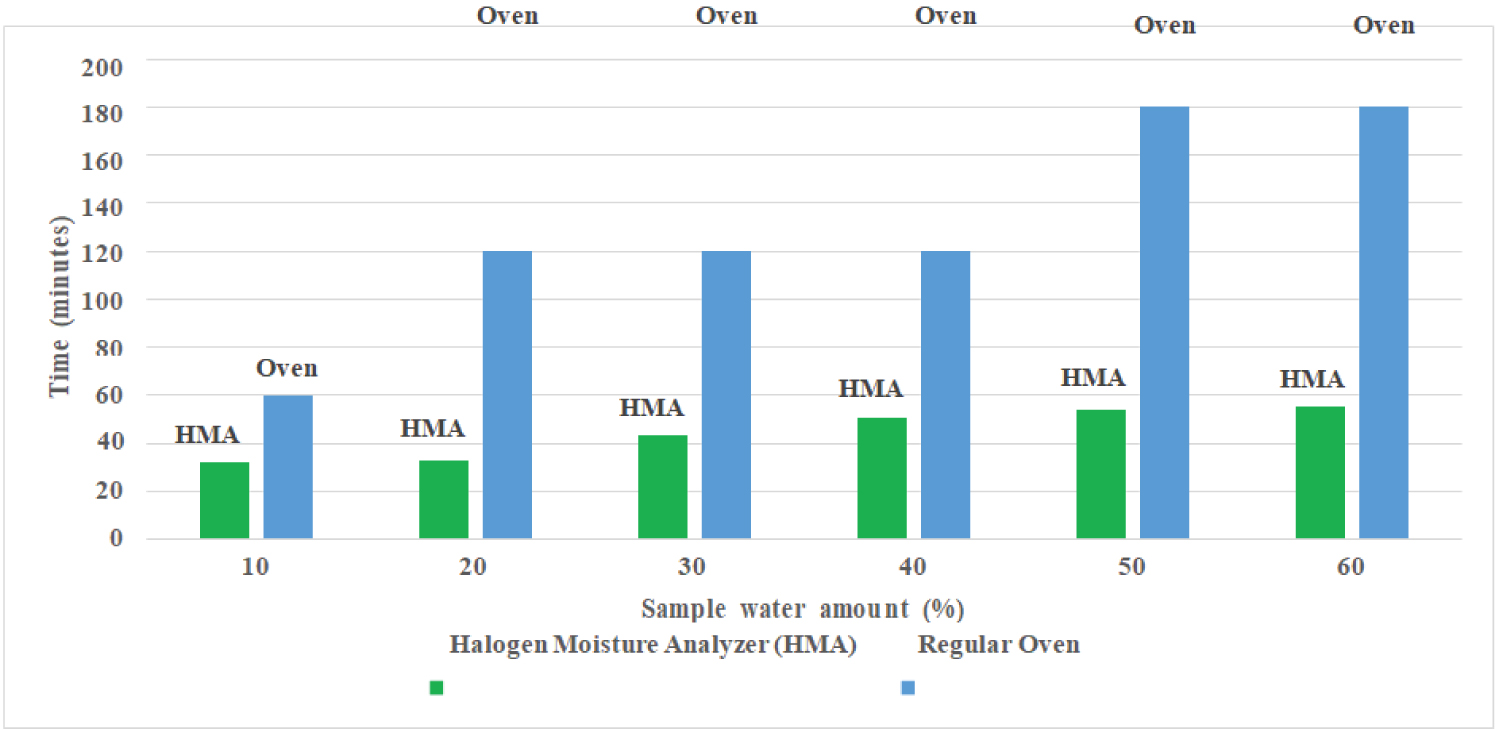

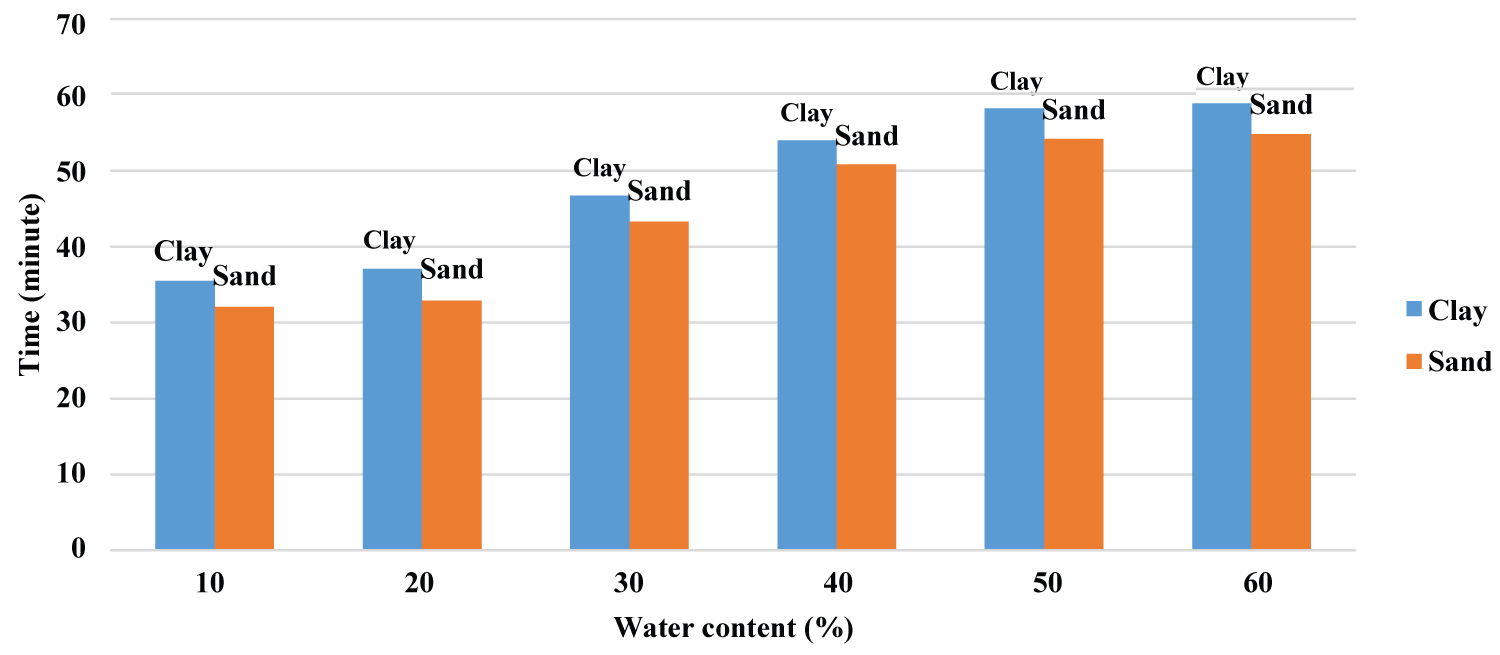

Figure 5 shows that the halogen moisture analyzer dries the sand specimens completely within 32 minutes to 55 minutes depend on the specimen moisture content. The drying time increases with the specimen moisture content. However, the required time to dry a sand specimen by using a conventional lab oven in comparison to a halogen moisture analyzer is significantly more. Table 2, Table 3 and Table 4 indicate the results of two measuring methods.

The correlation coefficient indicates the closeness of fit of the halogen moisture analyzer values versus drying oven values. It signifies that the results obtained from the conventional oven and halogen moisture analyzer have a perfect positive relationship.

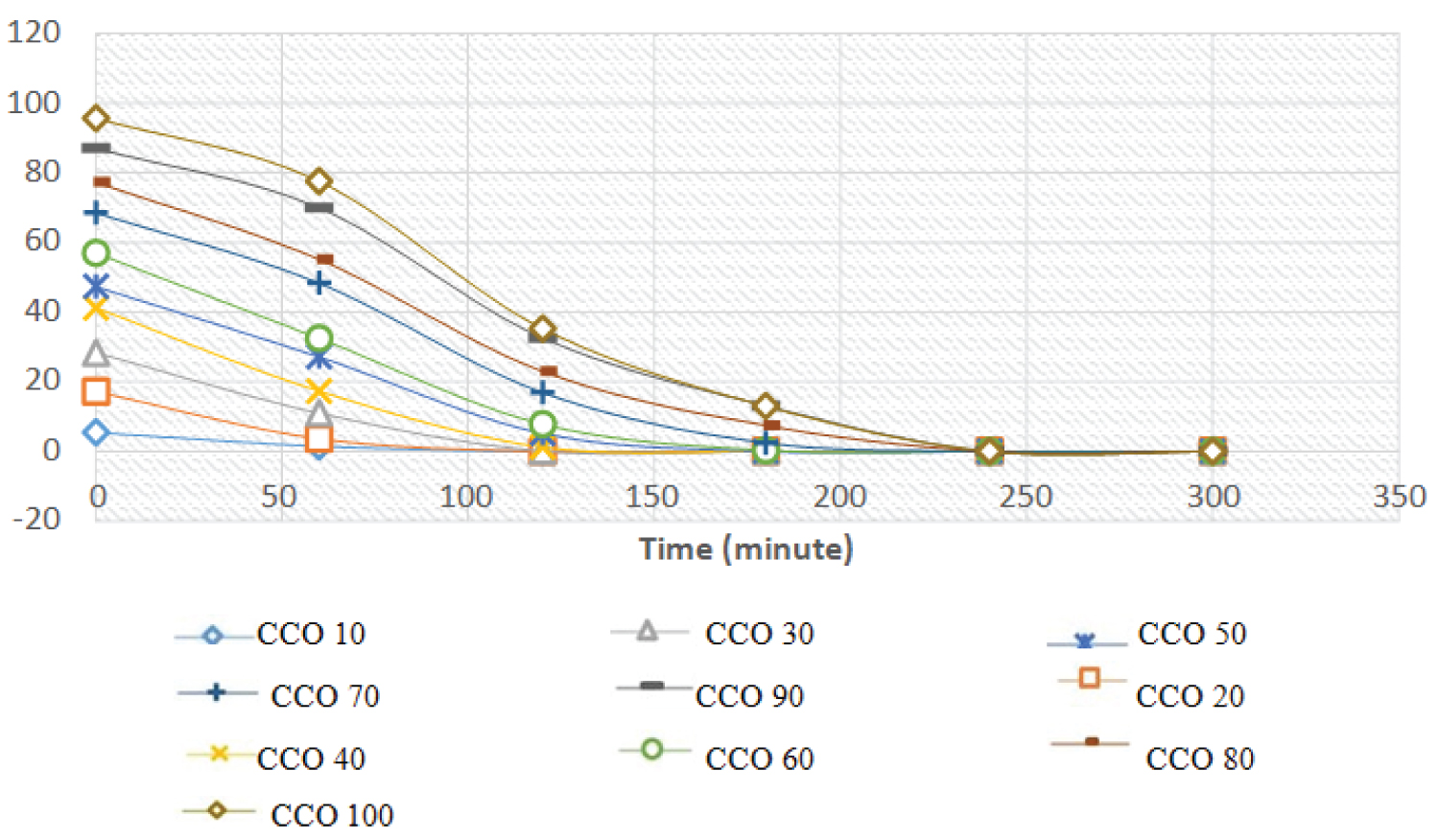

Similar tests were performed on the clay specimens to investigate the effect of soil type on drying time using both the conventional oven and the halogen moisture analyzer.

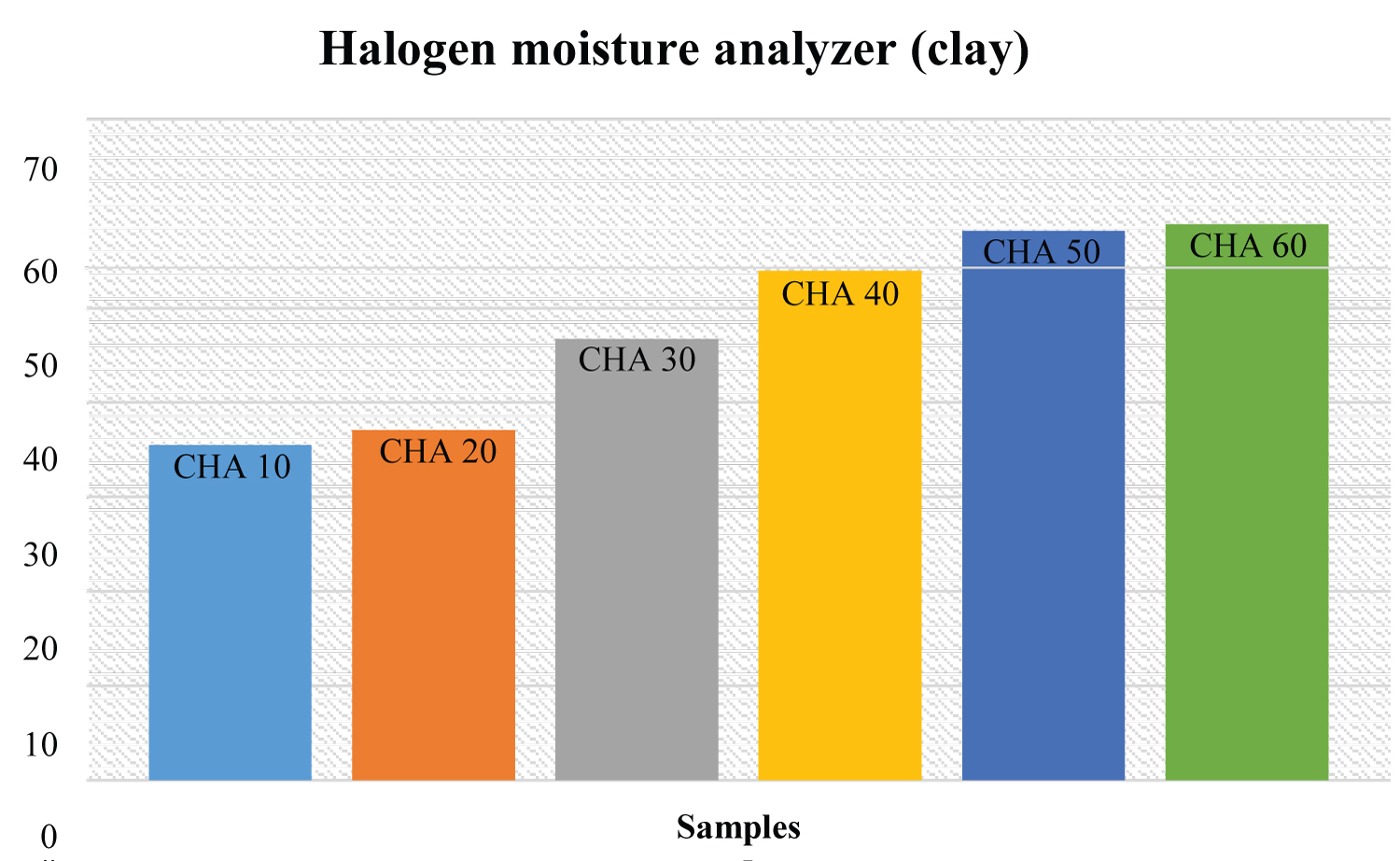

Figure 6 shows changes in the moisture content of the clay specimens for different initial water contents. While the total drying time for the clay specimen in the conventional oven is almost the same as for the sand specimens, the rate of losing moisture seems to be slightly slower for the clay specimens for the first 60 minutes, but the rate of losing moisture increases after an hour. The rate of losing moisture increases with an increase in the surface area of the specimen after forming the shrinkage (tensile) cracks after about an hour (Figure 6). Figure 7 shows the drying time for the clay specimens in the halogen moisture analyzer. Table 5, Table 6 and Table 7 indicate the results of two measuring methods.

The correlation coefficient is 0.98 showing the result obtains from the two methods have a perfect positive relationship. Also, the closeness of fit of the halogen moisture analyzer values versus drying oven values is proved.

Figure 8 shows the required time to dry the sand and clay specimens for a moisture content test by using the halogen moisture analyzer. As it is shown, the drying time for the clay specimens is about 10% more than the drying time for sand specimens. As expected, the drying time increases with increasing moisture content, and the maximum drying time for the highest moisture content in this study (60%) is less than an hour. The characteristic of the clay minerals can explain the higher drying time for the clay specimens. More thermal energy or more heating time is required to overcome the forces holding the water molecules due to the negative electrical charges on the surface of clay particles and the polarity of the water molecules.

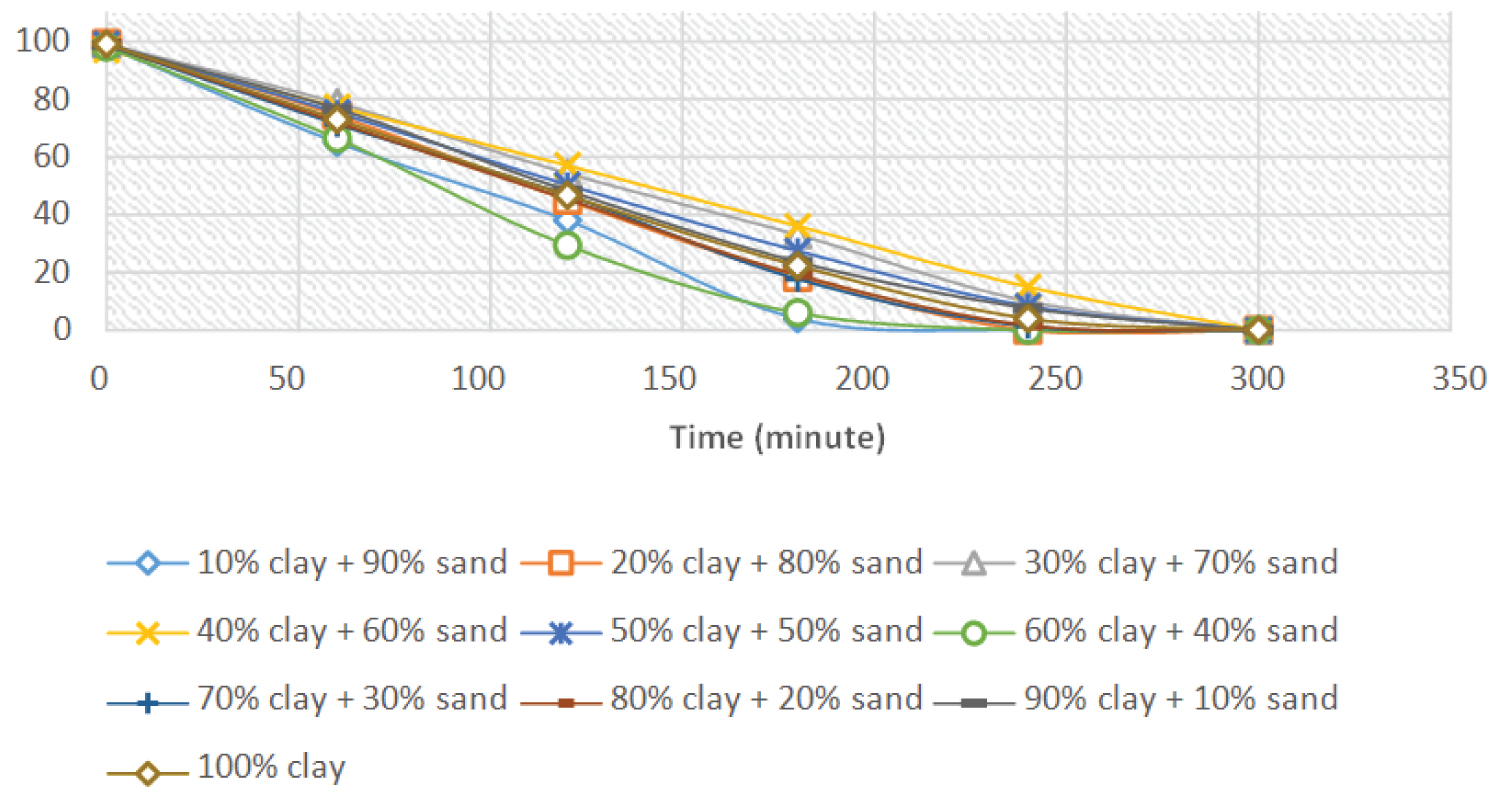

Similar results were achieved for specimens made of sand and clay. Figure 9 shows specimen moisture versus drying time for the specimens made of different percentages (by dry weight) of sand and clay in a conventional oven. The rate of losing moisture for a clay percentage of more than 60% (by dry weight of the soil) decreases with the drying time. Based on these results, drying time for the specimens containing 60% or more clay must be five hours as a minimum to obtain reliable water content. Similar results were obtained for a mixture of sand and clay (Figure 7) in the halogen moisture analyzer. The drying time rises with increasing moisture content, and the maximum drying time for the highest moisture content is less than an hour (Figure 10).

A comparison of the two methods (oven-dry method and halogen moisture analyzer method) to determine the soil's moisture content, along with advantages and disadvantages is presented in the following table. The maximum amount of soil the moisture analyzer is limited to specimen holder size; this specific equipment is limited to 50 g. therefore, for this investigation, the maximum water content that was applied was 60 percent (Table 8).

Conclusions

In this study, moisture content for soil specimens of silica sand, Kaoline clay, and mixtures of sand and clay were measured by the traditional method by using a conventional lab oven as a basis. The moisture contents of these specimens were measured by using a halogen moisture analyzer as well, and the results of the two methods were compared. The drying time depends on several different factors, including the moisture content of the soil, soil type, specimen size, and oven temperature.

A soil specimen made of silica sand or Kaoline clay or a mixture of both should stay in a conventional lab oven for at least five hours to lose its entire pore water following the ASTM D2216-19. The rate of losing moisture for specimens containing more than 60% clay is relatively slow at the beginning of the drying process, and this rate increases with the development of shrinkage cracks on the specimen surface after about an hour.

The drying time for the same soil specimen in a halogen moisture analyzer is as low as 60 minutes or less, depends on the initial moisture content of the specimen and soil type, which is significantly less than the drying time of a conventional lab oven. The statistics analysis result indicates that the halogen moisture analyzer provides comparable results to the drying oven method.

The specimen size of a halogen moisture analyzer, however, is small, and it is limited to the specimen holder size. Measurement of the soil moisture content using a halogen moisture analyzer is an automated process that minimizes user errors and mistakes. Besides, a halogen moisture analyzer is energy efficient as it stops the drying process once no significant changes in the specimen weight are detected. Therefore, a halogen moisture analyzer provides a reliable and relatively fast method to determine soil water content when the number and size of specimens are relatively small.

A drying oven can estimate several samples' moisture content simultaneously. It can handle many samples and larger masses; however, the drying time is significantly more, and additional instruments, such as a precise measuring scale and sample containers, are required. The halogen moisture analyzer is a portable automated unit suitable for measuring soil water content quickly.

Funding

Department of Mineral Engineering at New Mexico Institute of Mining and Technology provided the project funding for this research. The support of the department is acknowledged with many thanks.

References

- (2019) ASTM Standard D2216-19: Standard test methods for laboratory determination of water (moisture) content of soil and rock by mass. ASTM International, West Conshohocken, PA.

- Cooper JD (2016) Soil water measurement: A practical handbook. Wiley Blackwell.

- Reynolds SG (1970) The gravimetric method of soil moisture determination part I?: A study of equipment, and methodological problems. J Hydrol. 33: 258-273.

- Visvalingam M, Tandy JD (1972) The neutron method for measuring soil moisture content - A Review. J Soil Sci 23: 500-511.

- Gee GW, Dodson ME (1981) Soil water content by microwave drying: A routing prodedure. Soil Sci Soc Am J 1234-1237.

- Mohamed AM, Paleologos E (2018) Fundamentals of geoenvironmental engineering. Butterworth- Heinemann.

- Benedetto A, Benedetto F (2011) Remote sensing of soil moisture content by GPR signal processing in the frequency domain. IEEE Sens J 11: 2432-2441.

- Dean TJ, Bell JP, Baty AJB (1987) Soil moisture measurement by an improved capacitance technique, Part I. Sensor design and performance. J Hydrol 93: 67-78.

- Min L, Bing Cheng S, Wei H, et al. (2016) Single-probe heat pulse method for soil water content determination: Comparison of methods.

- Ren T, Ochsner TE, Horton R, et al. (2003) Heat-pulse method for soil water content measurement: Influence of the specific heat of the soil solids. Soil Sci Soc Am J 67: 1631-1634.

- (1991) ASTM D1193-91. Standard specification for reagent water. ASTM International.

Corresponding Author

Arezou Rasti, Department of Mineral Engineering, New Mexico Institute of Mining and Technology, 801 Leroy Pl, Socorro, NM, 87801, Po Box 2777, USA.

Copyright

© 2020 Rasti A, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.