A Geotechnical Approach in Sustainable Reuse of Mine Tailings: A Case Study of Tin Mine Sites in Plateau State, Nigeria

Abstract

This study investigated the geotechnical properties of tin mine tailings for its potential use, using particle size analysis, oedometer consolidation test, quick undrained triaxial test, compaction test and permeability test. The results showed that tailings from Caha1 and Kantoma1 have higher percentage of coarse than fine grains, lower moisture and optimum moisture content and higher coefficient of permeability. The most well graded materials of the mine tailings is CahaC. KantomaC and CahaC showed higher percentage of fines, high plastic, liquid and shrinkage limit, high plasticity index, high moisture content and optimum moisture content, higher shear strength, and lower coefficient of permeability. However, compression and swelling index of all the tailings are of low plastic clay and have very low swelling potential. Based on degree of plasticity, all the mine tailings in the study area are below the range of 1-5 hence, they are non-plastic material.

Keywords

Atterberg/consistency limit test, Geo-accumulation index, Modified proctor, Shear strength parameters, particle size analysis, Tin tailing reusability

Introduction

Mining activities started in Kuza in early 1700s, in Plateau State, near river channel, with the primacy goal of using the Tin mineral to make farm tools [1]. After many centuries, tin mining has been extended to areas like Zaria, Kano, Bauchi, Ilesha and Plateau provinces, with over 80% of the production coming from the Plateau [2,3]. Plateau State is the world's largest known deposit of columbite an ore of niobium found associated with tin. Tin has been found useful in the production of both domestic and industrial material because it is pliable and also malleable. Nevertheless, mining activities are always in association with tailings. This increases as the demand for minerals and metals increases. Tailings are the waste product of mining extraction and treatment [4]. They are often in slurry form with high water content. They have the potential of damaging the environment by releasing toxic metals, causing gulley erosion, mine collapse and sinkholes, and contaminating soil and water supplies both groundwater and surface water [5,6]. Mine tailings account for most of the environmental issues related to the extraction industry, with risks increasing due to steadily rising tonnage of low-grade ore and extreme weather events. This type of waste can cause severe damage to the environment during stockpiling as a result of the leaching of some harmful elements into the ecosystem [7]. Several tailings disposal methods adopted in order to maintain the normal mining operations include; disposal of dry or thickened tailings in impoundments or free-standing piles, backfilling underground mine workings, and subaqueous disposal. The most common disposal method is impoundment of tailings, tailings dam disposal and tailings reuse disposal [8]. Although not all tailings are hazardous waste, but free-standing piles tailings occupy land as well as uttering the quality of the surrounding atmosphere [9]. Recycling is very much encouraged in many European Union countries, which have relevant provisions in all waste management directives [10]. In Korea, China, the Netherlands, and Japan, reusing of tailings as construction material has been the case [10]. The main idea of tailings reuse disposal is to minimize the waste volume i.e. reducing the quantity/tonnages being piled up at various mine sites (turning waste into usable space). Tailing reuse encourages sustainable development by reducing environmental pollution/hazard and then conserves the natural resources. Mine tailing can be used either alone for embankments or mixed with stabilizing chemicals like fly ash (FA) and hydraulic road binder (HRB) for pavement applications. In area of building, bridge, dam and road construction, mine tailings can be stabilized chemically using admixtures like lime, calcium chloride, sodium carbonate, sodium sulphate, fly ash, bitumen, cement, etc or mechanically by compaction and consolidation. Tailing from iron can be used as pigment in the production of paint for buildings [11]. In the area of pottery/ceramics, chemical binder such as calcium-rich cement-like binder may be used to recycle mine tailings as raw materials in pottery/ceramic production [12]. Using these tailings also as a backfilling material can be cost-effective and eco-friendly solution for managing them. As a way reducing volume of tailing piles, tailings can also be used in cement and concrete [13]. There are several reports ranging from leaking to failed tailing dams which has lead to loss of many lives [14]. Another issue associated with reuse of mine tailings is hydraulic sorting as some mine tailings drain slowly maintaining residual moisture content under gravity drainage. Thus, the geotechnical characters of the mine tailings give one an edge on best way to reuse them. Thus, tailings possess different geotechnical properties depending on the type of ore extracted and the physical and chemical processes used in extracting the product. For instance, the cyclic resistance ratio (CRR) of laterite tailings increased with an increase in the initial effective consolidation stress, whereas the CRR of copper-gold-zinc tailings and gold tailings was insensitive to the initial consolidation stress [15,16]. Coal tailings have lower specific gravity than other minerals; copper tailings generally have higher hydraulic conductivity than gold tailings [17]. Geotechnical properties (particle size, permeability, moisture content, compressive strength, shear strength, Atterberg limit, etc.) of tailings have more significant impact on their reuse in terms of environmental sustainability, workability, stability, strength, durability and best stabilization method to adopt. Particle-size analysis helps in predicting soil-water movement, helps in the design of filters for earth dams and to determine suitability of soil for construction. Although this research focused more on the geotechnical properties of the mine tailings, however, knowing the mineralogical/chemical makeup of the tailings is another guide on its usage as some tailings may contain hazardous heavy metals/chemicals which may alter its durability [18,19]. It also helps in metals recovery, immobilization of hazardous metals, guide against the sulphide invasion/reactivity and valorizes mineral residues of the tailings.

In recent research, the role of geotechnical knowledge in the reuse of mine tailings especially tin mine tailings has not been quit extensive. Some of the researchers and analyst like Santiago, et al. [11], Ince [20], Esmaeili, et al. [21], Skarżyńska [22], Kim, et al. [23], Galvão, et al. [24] have given insight on the reuse on some mine tailing such as gold mine tailings, copper mine tailings, coal mine tailings, iron mine tailings, but no literature said much about the reuse of tin mine tailing. Thus, Wijewickreme, et al. [15], James, et al. [16] and Wang [17] from their findings made it clear that tailings from different ores possess different material properties. This spelt the need to research on the geotechnical properties of tin mine tailings for its potential reuse.

The objective of this study is to determine the potential use of tin mine tailing in some structural designs like roads, bridges, buildings, pottery/ceramics, etc based their geotechnical properties, as a way of remediating and sustaining the environment.

Features of the Study Area

Description of the study area

Plateau State has numerous hillocks with gentle slopes emerging from the ground like mushrooms scattered with huge boulders creating unusual scenery. Unfortunately, mining activities has disrupted the aesthetic beauty of this Plateau with characteristic mine tailings spreading over wide areas, deep mining pits, abandoned mine excavations (Figure 1a), mine ponds (Figure 1b), pilot ponds and failed earth dam/banks. Proper management of mine tailings is the main challenge facing mining activities in these areas, as this waste occupies some of the farm lands. This research paper will add to the body of knowledge on the efficacy of reusing tin mine tailings since there are few literatures in this area. The information provided in this work will also help the government and environmentalist in decision-making toward better environmental sustainability.

Geology and climate of the study area

Plateau State is one of the areas in Nigeria where older granite was intruded by younger granite. These younger granites are thought to be about 160 million-years-old. The study areas are underlain by five different lithologies ranging from Tertiary volcanoes to Cambrian basement complex (older granite). These lithologies are: basalt and phonolite trachytes, quartz porphyry, hornblende granite, coarse porphrytic biotite and biotite hornblende, and migmatite and granitic gneiss. The phases of volcanic activities involved in the formation of Plateau State have made it one of the mineral richest states in the country [25]. In Plateau State, tin (Sn), cassiterite and columbite are present in veins and pegmatites associated with rhyolites and granites intrusion, and can also be found in metamorphic rocks [26]. When the rock containing minerals are weathered, they remain intact and eventually concentrated in streams to form placer deposits [27]. However, most of the world's total Sn production is derived from secondary alluvial deposits resulting from the disintegration of the primary deposits [28]. In Plateau state, Sn deposit occurs in hard rock and also in alluvial deposit.

The climatic condition of the study area is characterized by wet season which goes from April to October and it is warm and muggy, with annual range of 1,000 to 1,500 mm [29,30]. Hot season lasts from February to April, with an average daily temperature, above 31 ℃. The hottest month of the year is March, with an average high of 33 ℃ and low of 18 ℃. The coldest month of the year is December, with an average low of 11.7 ℃ and high of 28.9 ℃. The State is 60% partly cloudy and 40% overcast or mostly cloudy. The clearer part of the year in Plateau begins in November and ends in February, with December being the clearest month of the year. The cloudier part of the year begins in February and ends in November, while May is the cloudiest month of the year [25]. April to October is muggier than December, when muggy conditions are unheard of, while June is the muggiest month of the year [30]. The wind most often comes from the West (around April to August), with a peak percentage of 51% on July, and East from August to April, a peak percentage of 73% on January. The windier part of the year is from November to April, while January is the windiest month of the year is [29].

Materials/Methodology

Sample collection

Four (4) samples were systematically collected from four (4) distinct mine sites at two (2) different locations (Caha and Kantoma), where open pit mining were active. The mine tailings were collected at varying depth of 13 ft (Caha 1), 12 ft (CahaC), 19.4 ft (Kantoma1) and 10.2 ft (KantomaC). Kantoma samples were collected from alluvium, while Caha were collected from weathered hard rock (metamorphic).

Laboratory analysis of the field data

The following geotechnical tests were carried out: Sieve analysis/grain size distribution, undrained triaxial test, oedometer consolidation test, permeability test and modified proctor compaction test.

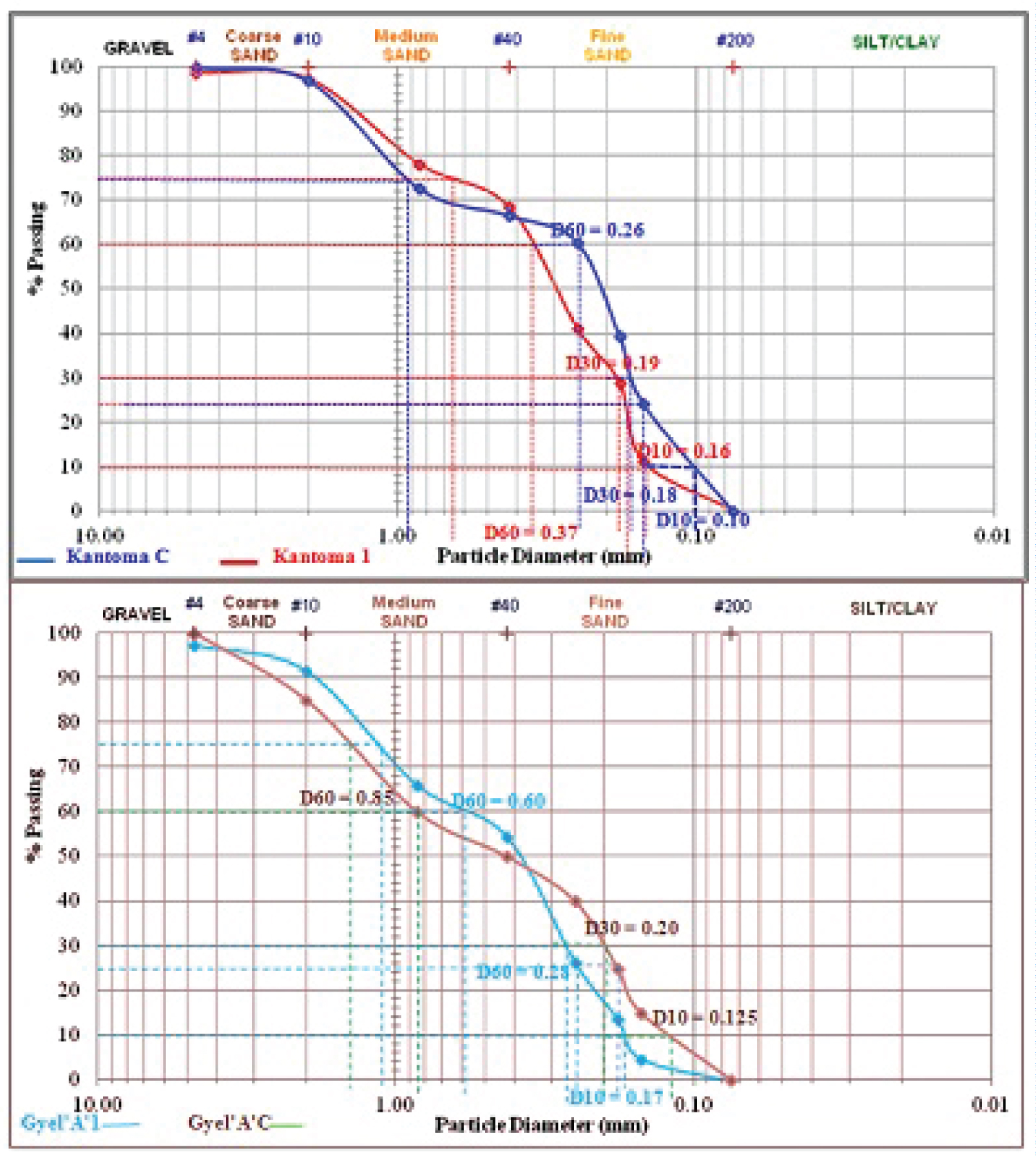

Sieve analysis/grain size distribution: The sieving method and particle size analysis for grain size distribution were carried out in accordance with British Standard: 1337 [31]. The particle size distribution of the soil was characterized using; coefficient of uniformity (Cu), coefficient of curvature (Cc), sorting coefficient (C) or (So), particle sizes D10, D25, D30, D50, D60 and D75 in mm and 10%, 25%, 30%, 60% and 75% by weight of soil, passing the respective sieve sizes [32-35]. Casagrande [33] on one hand calculates Cu and Cc as;

Cu ≥ 4 indicates a well-graded soil. Cu < 2 indicates a uniform soil. Cc between 1 and 3 indicate a well-graded soil.

Cc < 0.1 indicates a possible gap-graded soil.

While Folk [36] on the other hand presented a verbal classification scale for sorting (So), < 0.35: very well sorted; 0.35-0.500: well sorted; 0.5-0.71: moderately well sorted; 0.71-1.00: moderately sorted; 1.00-2.00: poorly sorted; 2.00-4.00: very poorly sorted; and, > 4.00: extremely poorly sorted.

Coefficient of uniformity, Cu, Coefficient of curvature (Cc) and sorting coefficient (So) are calculated from the curve as seen in the equations (Eq) (1) - (3).

Cu = D60/D10 (1)

Cc = D302/ D60 × D10 (2)

So = √D75/D25 (3)

Consolidation

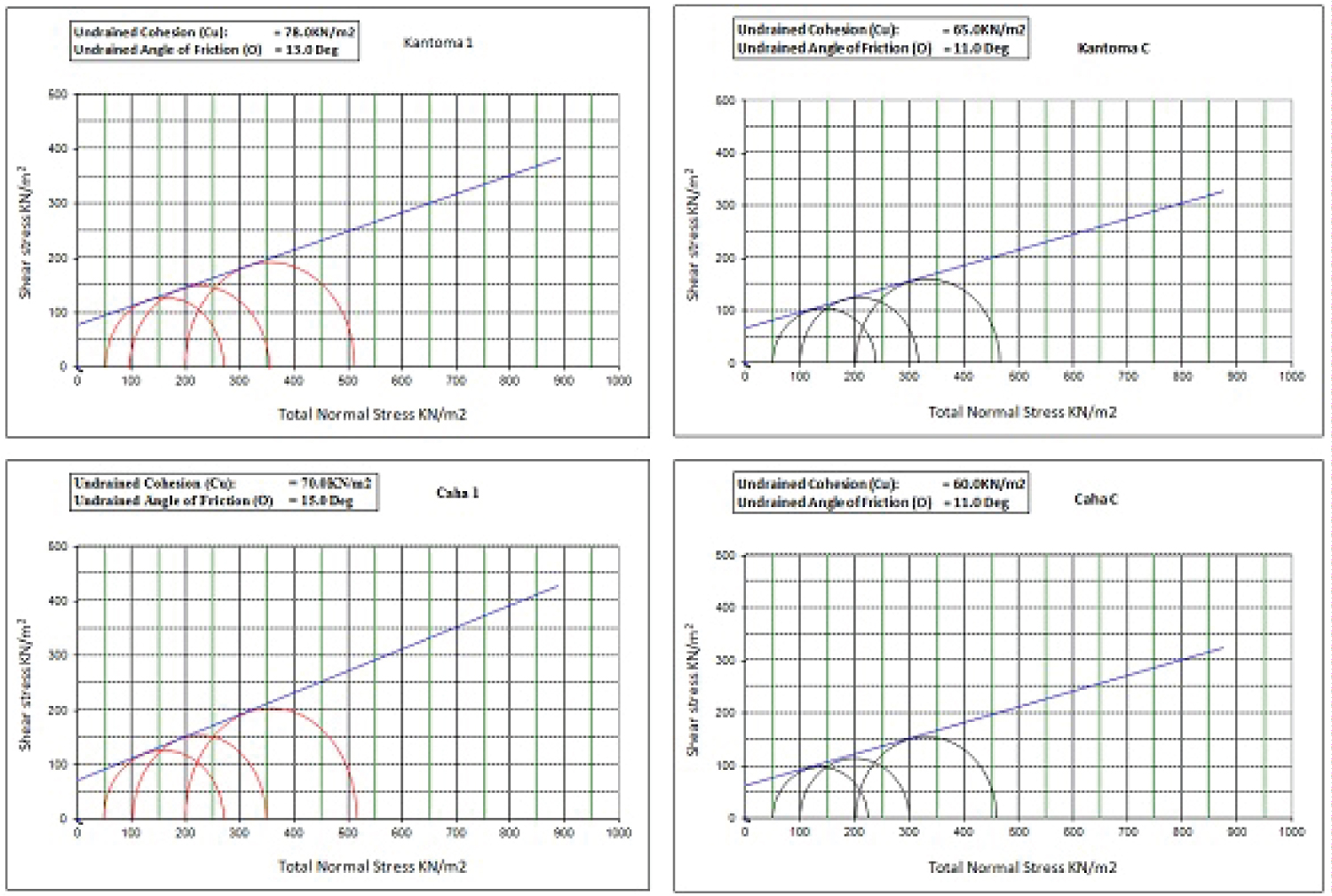

Quick undrained triaxial test: The shear strength properties of the tailings were determined by conducting quick undrained triaxial compressional tests on the samples based on ASTM D2487-11 and ASTM D4767-11 standard [37,38]. Undrained cohesion and angle of internal friction are the two major shear strength parameters and were deduced from the Mohr failure envelops. The stress results from the series of triaxial tests at increasing cell pressure, 50 kN to 200 kN were plotted on a Mohr stress diagram.

The shear strength was calculated using equation 4 [39].

S = C + σ tan φ (4)

Where S = shear strength;

C = cohesion, read of the shear stress axis, where it is cut by the tangent to the Mohr circles;

σ = normal stress;

φ = angle of shearing resistance or angle of internal friction is angle between the tangent and a line parallel to the shear stress.

But σ is obtained using equation 5

σ = σ1 + σ3/ 2 + σ1 – σ3/2 cos 2θ (5)

where, σ1 = the major principal plane;

σ3 = minor principal plane;

θ = 90.

The oedometer consolidation test: Oedometer test consolidation test was carried out on the four (4) remolded samples, measuring 71.4 mm in diameter and the height of 20 mm with load increment of 10 kN to 800 kN. The test was done in accordance to the ASTM D4767-11 [38] standard, The following soil properties were derived from the oedometer test:

Coefficient of compressibility (Mv): This determines the field behavior of the soil as the effective stress increases. It is calculated as

Mv = ΔH/H*1000/ΔP (m2/MN) (6)

Where; ΔH = Change in height, H = Initial height (mm), Hf = Final height (mm), P = change in pressure range

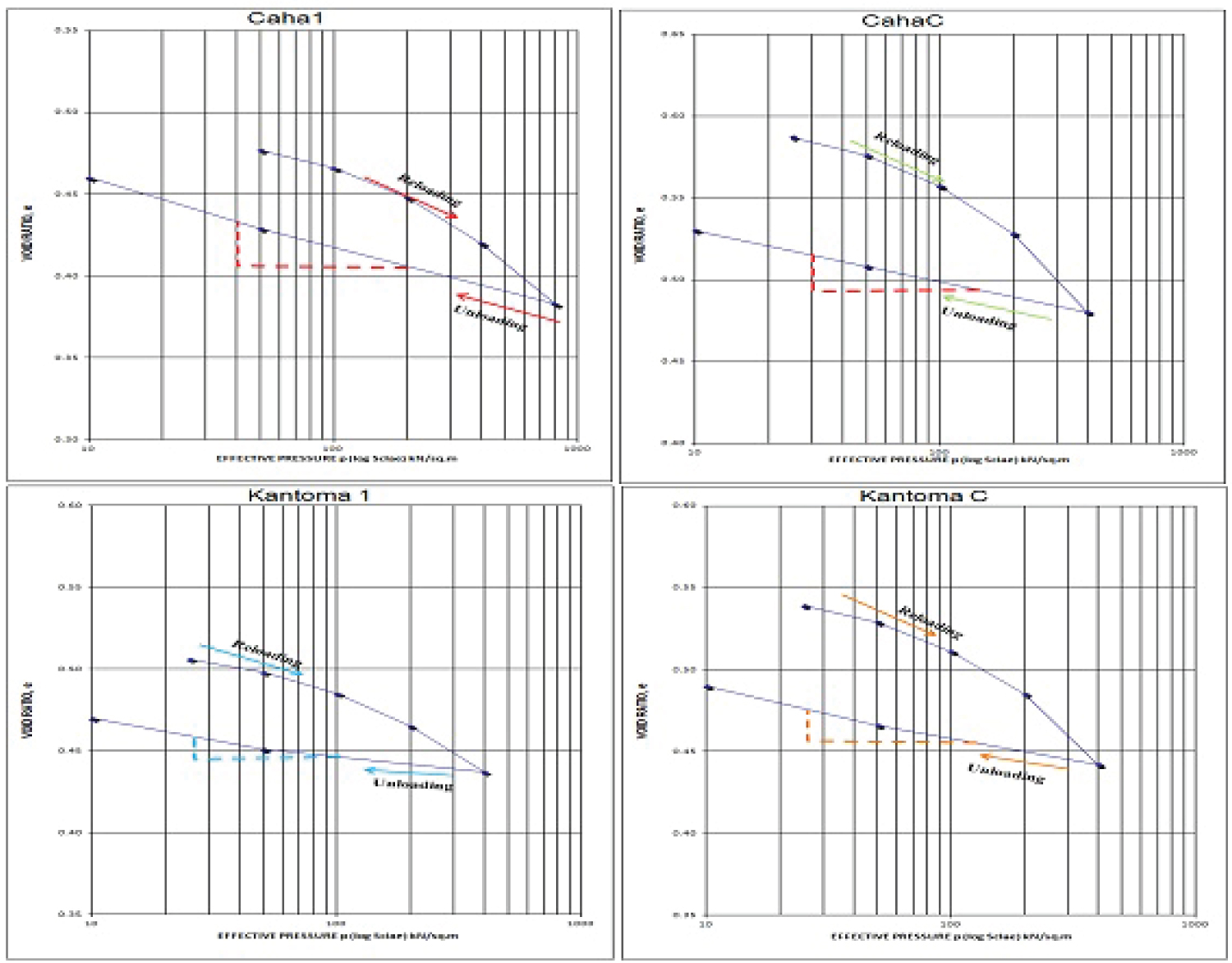

The Compression Index CC: CC is an index associated with the compressibility of the soil. It is extremely useful in determination of the settlement in the field. It is measured as the slope of the curve between void ratio and effective stress. The void ratio is plotted in a normal scale whereas the effective stress is in a logarithmic scale. A typical compression curve in terms of void ratio (e) and effective stress log Ϭ is presented in Figure 4. The Compression CC index is presented as:

CC = -Δe / log10 (Ϭ0 +ΔϬ/ Ϭ0) (7)

Where Ϭ0 = initial effective stress, Ϭ = final effective stress Δe = change in void ratio, and the negative sign indicates that the void ratio decreases with the increase in effective stress.

Compression index of clay is related to its index properties, especially with the liquid limit. Terzaghi and Peck [40] gave the following empirical relationship for clays of low to medium sensitivity (Si ≤ 4). Some empirical expressions that relate the Compression Index, CC, with the Liquid limit (LL) and Plasticity Index (PI) of the soil, are stated below:

For remoulded soils Cc = 0.007 (LL - 10) [40,41]. (8)

For undisturded soil Cc = 0.009 (LL - 10) [42] (9)

Cc = 0.50 × PI × Gs, [43] (10)

The value Cc varies between 0.30 for highly plastic clays and 0.075 for low plastic clays.

Expansion index or swelling index (Ce): The expansion index or swelling index Ce, is used as an indicator of the soil's swelling potential to determine the suitability of a soil to satisfy certain requirements. The recommended qualitative classification of potential expansion in a soil based on Ce is provided in Table 1 as per the ASTM D4829-11 [43]. Expansion index or swelling index Ce is the slope of the e - log Ϭ plot obtained during unloading. It is given as;

Ce = ∆e/log10 (Ϭ - ∆e/Ϭ) (11)

Liquid limit (LL): The value of liquid limit is used in soil classification of the soil and it gives an idea about plasticity of the soil. It is an indicator about the compressibility of the soil. The compressibility of the soil increases with an increase in liquid limit. It is calculated as;

LL = w (N/25) ^ 0.121 (12)

Where w is the moisture content, N is the number of blows and 0.121 is a constant. 0.121 is the power coefficient suggested by ASTM [44] for an inorganic soil sample corresponding to 25 blow counts.

In this study, 30 blow counts (N) were required for the closure of the opening in Casagrande cup and the power coefficient of one-point liquid limit equation given by ASTM [44] was used due to sample preparation technique ASTM-suggested power value of 0.121.

Plastic limit (PL): Plastic limit is as important as liquid limit so as to ascertain Plasticity index.

Plasticity limit is given as PL = (M2-M3/M3-M1) × 100 (13)

M1 = weight of ring

M2 = Weight of ring and wet soil

M3 = Weight of dry soil and ring

Shrinkage limit (SL): SL helps in design of structure made up of or resting on such soil. It helps in assessing the suitability of soil as a construction material in foundations, roads, embankments and dams [45].

SL = ((Mi-Ms) - (v1-v2))/Ms × ρw (14)

Where Mi = Initial weight of the wet soil

Ms = Weight of dry soil

V1 = Initial volume

V2 = Volume after drying

Ρw = Mass density of water

Plasticity index, PI indicates the fineness of the soil and its capacity to shape without altering its volume. Plasticity index in combination with liquid limit gives information about the type of clay [46]. Soils with a high PI tend to be clayey; those with a lower PI tend to be silt while those with a PI near zero tend to have little or no silt or clay (fines) present (Table 2). Plasticity index (PI) can be calculated using eq. 15.

PI = LL - PL (15)

Liquidity index (LI): It predicts soil properties at different moistures. LI of zero, 0 or lower indicates harder and more brittle soil. LI < 0, shows that the soil is in a semisolid state with characteristic high strength, brittle response and sudden fracture of the soil and if 0 < LI < 1, the soil is in a plastic state characterized by intermediate strength which deforms like a plastic material. If LI > 1, the soil is in a liquid state characterized by low strength; it deforms like a viscous fluid. Liquidity index is calculated as

LI = wi – PL/PI (16)

Where wi is the water content

Consistency index CI indicates the firmness/shear strength of a soil, as the CI increases, the shear strength of the soil increases. This is calculated as;

CI = LL - wi/PI (17)

Shrinkage index (SI) is an indicator used to determine the amount of clay and is given as;

SI = LL - SL (18)

Permeability test: The permeability of the Sn mine tailings was measured with a permeameter by applying a variable head gradient under different consolidation stresses (50 kN, 100 kN, 200 kN, 400 kN, and 800 kN). The specimens for the permeability tests were 18.6 mm in diameter and the tests were completely conformed to ASTM standard D5084-10 [47]. The permeability was determined at the end of each applied stress increment through direct measurement by variable head difference across the sample.

Compaction test: Compaction test was conducted using the Modified proctor test (ASTM Designation: D1557) because it is more precise compared to Standard Proctor test because mould in modified proctor test is filled in 5 layers compared to standard proctor test that is 3 layers. The more compacted the soil, the better results for optimum moisture content (OMC) and maximum dry density (MDD). This test determine the relationship between water content and dry unit weight of soils (compaction curve) compacted in a 4 in. or 6 in. diameter mold with a 10 Ib (4.54 kg) hammer dropped from a height of 18 in. (457 mm) producing a compactive effort of 56,250 ft (2,700 kN-m/m3). The whole soil sample was compacted in 5 layers with 25 evenly distributed blows on each layer [40,43]. The values of the optimum water content and maximum dry unit weight were determined from the compaction curve. Soil types can be identified based on optimum moisture content [46] (Table 3).

Geochemical analysis of the heavy metal in the soil: Twelve heavy metals (Ba, Cd, Cr, Co, Cu, Fe, Pb, Mn, Hg, Ni, As and Zn) were analyzed for each of the soil samples using specific hollow cathode lamp at a specific wavelength, and then aspirated into the flame of atomic absorption spectrophotometer (AAS, PerkinElmer Analyst 200).

Result and Discussion

Particle size analysis

Table 4 and Figure 2 summarized the result from particle size analysis and grain size distributions curve. Percentage of gravel is in the range of 2.80% to 14.90%, sand 72.8% to 86.5% and fines 5.10% to 24.2%. The tailing samples (Caha1 and Kantoma1) have more percentage of coarse particles than fines, whereas CahaC and KantomaC have higher percentage of fines than coarse particles. Due to higher percentage of coarse particles in Caha1 and Kantoma1 mine tailings, they can be reuse in the construction of downstream shoulder section of an embankment which requires mass and drainage [48], While KantomaC and CahaC, with their high percentage of fines, can be baked into bricks for building. Fine tailings can be used as fine aggregate replacement to enhance the density of fresh mortar/cement and effective in radiation shielding hardened mixture [9]. From the plot of soil percentages passing versus soil diameter, the characteristics indices of the soil were determined (Figure 2). Coefficient of uniformity (Cu) reviewed CahaC to be the most well graded soil among the mine tailings with coefficient of uniformity (Cu) (6.8) followed by Caha1 (3.53), while the two samples from Kantoma are poorly graded [31,34]. Coefficient of curvature (Cc) is highest in KantomaC (1.246) followed by Caha1 (0.769) while CahaC (0.376) is the least (Figure 2). In terms of sorting coefficient (So), CahaC has highest value and Kantoma 1 the least. According Folk [35] sorting classification scheme, the four soil samples calculated from the particle distribution curve (Figure 2) are well graded. They increase in following order; the two mine tailing Kantoma1 (1.900) poorly sorted, Caha1 (2.213), KantomaC (2.401) and CahaC (2.934) were very poorly sorted. In a well graded soil, smaller grains tend to fill the voids between larger grains and this in turn affect the hydraulic conductivity of the soil as well its permeability [31]. For geotechnical structures such as road construction, well graded soils are preferable whereas in drainage design, poorly graded material, such as mine tailings from Kantoma1 are better off [49,50].

Consolidation characteristics of the mine tailings

Consolidation is the compression of saturated soil under a steady static pressure due to expulsion of water from the void. The consolidation of fine tailings is normally slower than the coarse tailings due to low permeability [52]. It predicts the magnitude and the rate at which settlement occurs as well as its usage as a construction and foundation material. Hence, the Coefficient of compressibility (Mv), compression index (Cc), swelling index (Ce) and Atterberg limits were determined [35].

Coefficient of compressibility (Mv): Increase in effective stress from 50 kN to 800 kN/m2, decreases the void, but this effect later increase, as the load decreases, from 800 kN to 50 kN and 10 kN (Table 5 and Figure 3). CahaC and KantomaC have the highest void ratio (e) and coefficient of compressibility (Mv) values at various levels as the effective stress increases than Caha1 and Kantoma1 (Figure 3). This actually validates the result from particle size (Table 4). Thus, the higher the void ratio and percentage of fines in a sample, the higher the coefficient of compressibility [53]. Although, mine tailings are environmentally friendly materials in backfilling of mine pits as well as reclaiming the environment and reducing its volume on the surface [54], CahaC and KantomaC will tend to settle more than Caha1 and Kantoma1 when loaded with structures given the higher coefficient of compressibility [55-57]. This means that in using Caha1 and Kantoma1 either as a backfilling material in mine pits or filling material in foundation require little or no add mixtures whereas in CahaC and KantomaC mine tailings add mixtures are necessary to reduce settlement.

Compression index Cc: The result displayed in Table 5 showed that the tailings are of low plastic clay since they are all less than 0.30 [37].

Swelling index Ce: Based on ASTM D4829-11 classification [41], the tailings have very low swelling potential because they are below the range of 0-20 (Table 5). The results revealed that the soils have low affinity for water and are well drained. Ubido, et al. [56] revealed that Kaolinite is the only clay mineral that has the least affinity for water among the clay minerals. Materials with very low swelling potential are highly recommended in the road, bridge, dams and building construction [58]. Hence both mine tailings from Caha and Kantoma can be reused for constructional purposes.

Atterberg and consistency limit results: From the oedometer consolidation test result, Atterberg and consistency limit of the mine tailings were determined (Table 6). The results of Atterberg limit reviewed that CahaC has the highest plastic, liquid and shrinkage limit, followed by KantomaC, while the lowest is Caha1. However, liquid limit of all the mine tailings are very low since they are below 20 in the classification scheme (Table 1).

In terms of consistency limit, KantomaC (0.350) and CahaC (0.364) have higher plasticity index value than Kantoma1 (0.283) and Caha1 (0.243). This suggests that KantomaC and CahaC contain more clay than Kantoma1 and Caha1 [44], this result is in agreement with the result from sieve analysis (Table 4). Although based on degree of plasticity (Table 2), all the mine tailings are non plastic because they are below the range of 1-5, but in ceramics industry, KantomaC and CahaC are more preferable in pottery making than Kantoma1 and Caha1 since they have higher plasticity index. Just like plasticity index, shrinkage index is also higher in Kantoma C (5.497) and CahaC (5.574) than in Kantoma1 (4.314) and Caha1 (3.651). However, based on degree of expansion (Table 1), the mine tailings have low shrinkage index (Table 6). Based the findings of Shettima, et al. [59] mine tailings help in lowering the drying shrinkage of concrete.

Compaction test

Compactive effort of 25 kN to 800 kN was done to obtain the optimum moisture content (OMC) and maximum dry density (MDD) (Table 7). Compaction test result showed that Caha1and Kantoma1 have lower moisture content and optimum moisture content (OMC) of 12.0% and 14.0% but higher maximum dry density (MDD) (1.788 mg/m3 and 1.736 mg/m3) while CahaC and KantomaC have higher moisture content and optimum moisture content (18.0% and 17.0%) but lower maximum dry density (1.646 mg/m3 and 1.698 mg/m3). This suggest that OMC for Caha1 and Kantoma1 fall in the range of well graded sand (12%-14%) while CahaC and KantomaC fall in low plasticity silt-clay (17%-18%) [39]. Caha1 and Kantoma1 are more suitable in road construction while CahaC and KantomaC are better used in plastering of wall, flooring and brick baking since they have more of fines.

Quick undrained triaxial compression test

Shear strength is the most important geotechnical property which gives insight on the capability of a soil to support structural load, analyze and solves stability problems. Soils are essentially frictional materials comprised of individual particles that can slide and roll relative to one another. Its shear strength depends indirectly on the soil permeability and directly on the effective stresses, size and gradation of the individual particles, void ratio or dry density, and (e) confining pressure [60]. Quick undrained triaxial test carried out on Caha and Kantoma Sn mine tailings showed increase in compressive stress with increase in cell pressure of 50 kN to 200 kN. Here three different cell pressure tests were drawn in terms of effective stresses corresponding to failure conditions. Caha1 (70°) and Kantoma1 (75°) have higher undrianed cohesion as well as angle of internal friction (15° and 13°) CahaC and KantomaC (Table 8 and Figure 4). From the calculated shear strength (Table 8), kantomaC has the highest shear strength (18.344) followed by CahaC (16.26) while Kantoma1 (12.657) and Caha1 (0.9935) have the least values. This suggests that KantomaC and CahaC will be less prone to rutting by shear compared to Caha1 and Kantoma1. Thus Caha1 and Kantoma1 as foundation material require more stabilizer than CahaC and KantomaC, understanding the shear strength properties of the tailings aids in their specific usage. For instance, Guo, et al. [9], Fisonga, et al. [61], Sant'ana, et al. [62] and Thomas, et al. [63] discovered that increase in compressive strength of concrete improves with increasing tailing contents, but not beyond a limited replacement content of fine aggregates.

Permeability test

The amount, distribution, and movement of water in soil, safety of hydraulic structures, the stability of foundations, excavation of open cuts in water bearing sand, rate of flow of water into wells perhaps are ascertain from permeability test [50]. Permeability tests results displayed on Table 4, showed that Caha1 (9.205 × 10-6 cm/Sec) is the highest in average coefficient of permeability (kav) while CahaC (7.756 × 10-6 cm/Sec) is the least. This result is in agreement with the findings of Hu, et al. [53], who stated that metal tailings generally present larger hydraulic conductivity. Moreover, Caha1 and Kantoma1 have lowest moisture content, void ratio and porosity respectively than the other two (CahaC and KantomaC). According to Ukah, et al. [32], increment in the percentage of fines affects the soil gradation as well as the permeability. Guo, et al. [9] states that permeability is an important properties of the tailings that affects it durability especially, in terms of its usage in concrete, the lower the permeability of a concrete material, the better the durability. For sustainability of geotechnical structures such as pavement structure, these high permeable tailing materials can be reused for pavement construction with proper mix design and admixtures [64]. Caha1 mine tailings are the most permeable of the entire sample owing to its low percentage of fines. This might be the reason tailings were littered around the mine sites in the study area, since permeability encourages erodibility of the tailings/soil due to lack of shear resistance. Although in terms of construction of impoundment earth dams, these tailings can only be reuse with proper admixtures/stabilizers, but they can also be reuse in the design of downstream embankment that requires drainage [65] (Table 9).

Geochemical quality of the soil

The geochemical quality of the soil was determined using geochemical accumulation index (I-geo). According to Muller [66] Geochemical accumulation index (I-geo) consists of five classes: I-geo < 1 unpolluted, 1 ≤ I-geo < 2 indicates low pollution, 3 ≤ I-geo < 4 moderately polluted, 4 ≤ I-geo < 5 strongly polluted, and I-geo > 5 is extremely polluted. I-geo is calculated as

1− geo = Log2 (Cn/1.5Bn) (19)

Where Cn is the concentration of the metal pollutant, Bn is the geochemical background concentration of the pollutant in sediment, and 1.5 is the background matrix correction factor due to lithogenic effect. DPR [67] allowable concentration of heavy metals in the soil was used as the background value in both samples (Table 10). Based on the I-geo analysis in Table 11, The soil samples analyzed were all in the neighborhood of unpolluted (Kant2, Ni (1.010); kant3, Cd (1.128); Ni (1.015); Zn (1.274); Caha 1, Co (7.817); CahaC2, Zn (1.086) except Caha1 which is extremely polluted with Co (Co, 7.817). health wise, soil samples from Caha 1 cannot be used in the production of domestics wares as exposure to high levels of cobalt through ingestion causes asthma, pneumonia, nausea and vomiting, vision problems, dermatitis, thyroid damage, severe damage to the heart, and even death [68,69]. However, the presence of Co in construction material improves its durability and hardness at higher temperatures and reduces corrosion [70]. This makes sample from Caha 1 a better material for construction purposes.

Conclusion

The potential reuse of tin mine tailings from Gyel'A' popularly pronounced as Caha and Kantoma area of Plateau state, north central, Nigeria was investigated using the following geotechnical techniques: particle size analysis, oedometer consolidation test, quick undrained trial axial test, modified proctor compaction test and permeability test. The investigation showed that tailings from Caha1 and Kantoma1 have high percentage of coarse material, lower moisture and optimum moisture content and higher coefficient of permeability. These make them more preferable as a backfilling material in mine pits or as a filling material in foundation, construction of downstream shoulder section of an embankment, pavement construction with proper mix design and admixture than CahaC and KantomaC. However, KantomaC and CahaC showed higher percentage of fines, high plastic, liquid and shrinkage limit, high plasticity index, high moisture content and optimum moisture content, higher shear strength, and lower coefficient of permeability. Although, geochemical properties of the samples showed the entire sample to be in the neighbourhood of unpolluted except Caha1 which was extremely polluted with Co, thereby making it unfit as a raw material for the production any domestic wares. But, considering the geotechnical qualities CahaC and KantomaC possess, they samples can be baked into bricks for building, and also in pottery while Caha1 is at advantage for construction purposes, as it is highly concentrated in Co. Based on the geotechnical properties especially very low swelling potential and other qualities observed in all the Sn mine tailing samples from the study area, the tailings can recommended in the road, bridge, dams and building construction.

Acknowledgement

Authors appreciate members of the Environmental and Engineering Geology group of the University of Nigeria, Nsukka, Enugu State, Nigeria for their contributions and insights during the course of this research. We are especially happy at the effort and hard work the laboratory analysts/technicians put into this research.

Disclosure Statement

The authors hereby declare that there is no competing interest regarding this paper.

Data Availability Statement

The authors confirm that the data supporting the findings of this study are available within the article as well as available on request from the corresponding author [Bernadette U Ukah].

References

- Cooper N (2012) Tin Mining on the Jos Plateau. Open Edu Res 230.

- U.N Report (2017) Dangers of mine waste highlighted in U.N report.

- Suzuki T (2003) Economic and geographic backgrounds of land reclamation in Japanese ports. Mar Pollut Bull 47: 226-229.

- Ajaegbu H, Adepetu I, Ajakpo AA, et al. (1992) Jos Plateau Environmental Excursion Guide. Jos Plateau Environmental Resources Development.

- Marta-Almeida M, Mendes R, Amorim FN, et al. (2016) Fundao dam collapse: oceanic dispersion of River Doce after the greatest Brazilian environmental accident. Marine Pollution Bulletin 112: 359-364.

- Kundu S, Aggarwal A, Mazunder S, et al. (2016) Stabilization characteristics of copper mine tailings through its utilization as a partial substitute for cement in concrete: preliminary investigations. Environmental Earth Science 75.

- Kim SK, Yang D, Rao SV, (2012) A new approach to the recycling of gold mine tailings using red mud and waste limestone as melting fluxes. Geosystem Engineering 15.

- Hodder BW (1959) Tin Mining on the Jos Plateau of Nigeria. Econ Geog 35: 109-122.

- Terzaghi K, Peck RB (1967) Soil Mechanics in Engineering Practice, John Wiley & Sons, New York, 729.

- Grubesa IN, Barisic I, Fucic A, et al. (2016) The Indian experience of steel slag application in civil engineering In characteristics and uses of steel slag in building construction. Woodhead publishing, 141-160.

- Galvão JLB, Andrade HD, Brigolini GJ, et al. (2018) Reuse of iron ore tailings from tailings dams as pigment for sustainable paints, Journal of Cleaner Production 200: 412-422.

- Santiago G, Isabel S, Raquel VV M, et al. (2018) Coal-mining tailings as a pozzolanic material in cements industry. Minerals 8: 46.

- Onwuka SU, Duluora JO, Okoye CO (2013) Socio-economic impacts of tin mining in Jos, Plateau State, Nigeria. Int J Eng Sc Inv 30-34.

- Ahmed SI, Siddiqua S (2014) A review on consolidation behavior of tailings. Int J Geotech Eng 8: 102-111.

- James M, Aubertin M, Wijewickreme D, et al. (2011) A laboratory investigation of the dynamic properties of tailings. Can Geotech J 48: 1587-1600.

- Stephens T (2010) Manual on small earth dams. A guide to siting, design and construction. Food and Agriculture Organization of the United Nations Rome.

- Agency for Toxic Substances and Disease Registry (ATSDR) (2004) Public Health Statement on Cobalt.

- Wroth CP, Wood DM (1978) The correlation of Index Properties with Some Basic Engineering Properties of Soils. Canadian Geotechnical Journal 15: 137-145.

- Wilson SD, Squier R (1969) Earth and rock-fill dams. State-pf-the-art. Report. Seventh International Conference on Soil Mechanics amd Foundation Engineering, Mexico, 137-223.

- Franks DM, Boger DV, Côte CM, et al. (2011) Sustainable development principles for the disposal of mining and mineral processing wastes. Resour Policy 36: 114-122.

- Ubido OE, Igwe O, Ukah BU (2020) Evaluation of road failure along an erosion prone highway in Ogun state southwestern Nigeria using integrated methods. SN Appl. Sc.Doi:10.1007/s42452-020-03849-x.

- ASTM (2001) Standard Test Methods for Liquid Limit, Plastic Limit and Plasticity Index of Soils. Annual Book of ASTM Standards, Vol. 04.08, ASTM International, ASTM D4318-00 West Conshohocken, PA, 1-14.

- Ukah BU, Ubido OE, Igwe O (2021) Modeling and characterization of mine pit backfilling/reclamation materials around Gyel'A' and Kantoma areas of Plateau state using integrated method. Model Earth Syst Environ.

- Shettima AU, Hussin MW, Ahmed Y, et al. (2016) Evaluation of iron ore tailings as replacement for fine aggregate in concrete. construction and building materials. 120: 73-79.

- Sant'ana JN, Da Silva SN, Siva GC, et al. (2017) Technical and environmental feasibility of interlocking concrete pavers with iron ore tailings from tailings dam. Journal of Materials in Civil Engineering 29: 1-6.

- Ukah BU, Ubido OE, Igwe O (2020) Geo-statistical assessment of the soil quality and its influence on groundwater pollution in some part of Lagos State Nigeria. Model. Earth Syst Environ 6: 953-965.

- Coulomb CA (1776) Essai sur une application des regles de maximis et minimis a quelqes problemas de stratique relatifs a l'architecture. Memoires de mathematique et de physique. Presentes a l'Academie Royale des Sciences Paris 7: 343-382.

- Koerner RM (1999) Designing with geosynthetics. Pretice-Hall. Upper Saddle River, NJ, USA, 761.

- Hu L, ASCE AM, Wu H, et al. (2017) Geotechnical properties of mine tailings. J Mater Civ Eng 29.

- Johari NN, Bakar I Razali SNM, Wahab N (2016) Fiber effects on compressibility of peat. IOP Conf. series: Materials Science and Engineering 136.

- Müller G (1969) Index of geoaccumulation in sediments of the Rhine River. J Geo 2: 108-118.

- DSHS. What is cobalt? Texas Department of State Health Services Environmental and Injury Epidemiology & Toxicology Group 1100 West 49th Street, MC 1964 Austin, Texas 78756. Retrieved on May 10th from.

- (2020) Weather spark, Average weather in Jos Nigeria. Retrieved from weatherspark.com on 20th of June 2020.

- (2020) Weather-nga Jos climate. Retrieved from weather-nga.com on 20th of June 2020.

- Argane R, Benzaazoua M, Hakkou R, et al. (2016) A comparative study on the practical use of low sulfide base metal tailings as aggregates for rendering and masonry mortars. Journal of Cleaner Production 112: 914-925.

- Liu R, Huang F, Du R, et al. (2015) Recycling and utilisation of industrial solid waste: an explorative study on gold deposit tailings of ductile shear zone type in China. Waste Manag Res 33: 570-577.

- Wijewickreme D, Khalili A, Wilson WG (2010) Mechanical response of highly gap-graded mixtures of waste rock and tailings. Part II: Undrained cyclic and post-cyclic shear response. Can Geotech J 47: 566-582.

- Esmaeili J, Aslani H, Onuaguluchi O, et al. (2020) Reuse Potentials of Copper Mine Tailings in Mortar and Concrete Composites. Journal of Materials in Civil Engineering.

- Folk RL (1968) Petrology of Sedimentary Rocks. Austin, Texas.

- Victor NK (2017) Problems Related to Soil identification and classification. Soil Mechanics, Butterworth- Heinemann 51-92.

- ASTM (2011) Standard test method for expansion index of soils. ASTM International. ASTM D4829 – 11.

- ASTM (2009) Standard test methods for particle size distribution (gradation) of soil soil using sieve analysis. ASTM International, ASTM D6913-04.

- Fisonga M, Wang F, Mutambo V (2019) Sustainable utilization of copper tailings and tyre-derived aggregates in highway concrete traffic barriers. Construction and Building Materials 216: 29-39.

- Thomas BS, Damare A, Gupta RC (2013) Strength and durability characteristics of copper tailing concrete. Construction and Building Materials 48: 894-900.

- Ubido OE, Igwe O, Ukah BU (2018) Integrated Geological, Geophy Sicaland Geotechnical Assessment of Building Failure in Lagos; A Case Study of Ogudu Lagos South Western Nigeria. Int. J. Basic & Applied Sc 17.

- Skempton AW (1944) Notes on the Compressibility of Clays Q J Geol Soc. London, 100: 119-135.

- ASTM (2010) Standard test methods for measurement of hydraulic conductivity of saturated porous materials using a flexible wall permeameter. ASTM D5084-10, West Conshohocken, PA Williams CL, Brye.

- Ukah BU, Igwe O, Ubido OE (2019) Influence of soil particle size distribution on groundwater quality around industrial areas of Oshodi-Lagos Nigeria. J Water Soil Sc.

- ASTM (2020) Standard test methods for consolidated undrained triaxial compression test for cohesive soils. ASTM D4767-11 West Conshohocken, PA.

- Hobert King M (2005) Cassiterite mineral properties and uses.

- Casagrande A (1948) Classification and identification of soils. Trans Amer Soc Civil Eng 113: 901-930.

- Wang Z, Wong RCK, Qiu W (2017) Reconsidering secondary compressibility of soil. Int. J Civ Eng 15: 411-418.

- Langfelder LJ, Nivargikar VR (2020) Some Factors Influencing Shear Strength and Compressibility of Compacted Soils. Paper sponsored by Committee on Compaction and presented at the 46th Annual Meeting. Retrieved from on 23rd of August 2020.

- Thorpe D, Zhuge Y (2010) Advantages and disadvantages in using permeable concrete pavement as a construction material. In: Egbu C, Procs 26th Annual ARCOM Conference, 6-8 September 2010, Leeds, UK. Association of Researchers in Construction Management, 1341-1350.

- British Standard Institute BS: 1337 (1990) Methods of tests for soils for civil engineering purposes. Part 5. British Standards Institute Park street London, United Kingdom W1A 2BS.

- Ince C (2019) Reusing gold-mine tailings in cement mortars: Mechanical properties and socio-economic developments for the Lefke-Xeros area of Cyprus, Journal of Cleaner Production 238: 117871.

- ASTM (2011) Standard practice for classification of soils for engineering purposes (unified soil classification system. ASTM D2487-11 West Conshohocken, PA.

- DPR (2002) Environmental guidelines and standards for the petroleum industry in Nigeria (revised edition). Department of Petroleum Resources, Ministry of Petroleum and Natural Resources, Abuja.

- Paivo K, Arnold I, Soili S, et al. (2017) Recycling mine tailings in chemically bonded ceramics - A review. Journal of Cleaner Production 174.

- Li C, Sun HH, Yi ZI, et al. (2010) Innovative methodology for comprehensive utilization of iron ore tailings Part2: The residues after iron recovery from iron ore tailings to prepare cementitious material. Journal of Hazardous Materials 174: 78-83.

- Sumaila FAG (1989) Accessibility and rural development, relationship in tin mining region of Jos Plateau. Main Report September, published by Authority, Jos 11th November, Jos Government Printer, 9: 31.

- Wang YC (2019) Synthesis of geotechnical properties of mine tailings”. Electronic thesis and dissertations for graduate school Master.

- Calvin, Rosann H (2003) Tin. retrieved 20th of May 2020 from www.scienceviews.com.

- Onur EM (2014) Predicting the permeability of sandy soils from grain size distributions. MSc. Thesis, Kent State University.

- Fikret K, Mustafa A, Selçuk K, et al. (2018) Effect of cobalt content on the microstructure and toughness-hardness properties on p91 weld metal. 5th International Conference on Welding Technologies and Exhibition (ICWET'18) 26-28 September 2018, Sarajevo-Bosnia and Herzegovina.

- Ndace JS, Danladi MH (2012) Impacts of Derived Tin Mining Activities on Landuse/Landcover in Bukuru, Plateau State, Nigeria J Sustain Dev 5: 90.

- Arora KR (2004) Soil mechanics and foundation Engineering. Standard Publishers Distributors, Delhi, 903.

- Skarżyńska KM (1995) Reuse of coal mining wastes in civil engineering-Part 1: Properties of minestone, Waste Management, 15: 3-42.

- Ma W, Schott D, Lodewijka G (2017) A new procedure for Deep sea mining tailings disposal. Minerals 7: 47.

- Guo M, Zhou L, Ying NW (2019) Utilization of tailings in cement and concrete: A review. Science and Engineering of composite Materials 26: 449-464.

Corresponding Author

Bernadette U. Ukah, Department of Geology, University of Nigeria Nsukka, Nigeria, Tel: +2347038479934.

Copyright

© 2023 Ukah BU, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.