Thermo-Stability of Heat-Labile Contagious Bovine Pleuro-Neumonia Vaccine in Different Stabilisers

Abstract

All available vaccines for Contagious Bovine Pleuropneumonia (CBPP), a notifiable, highly contagious and fatal respiratory disease of cattle caused by Mycoplasma mycoides subsp. mycoides (Mmm), are heat-labile and still reliant on cold-chain technologies to ensure stability. With the associated significant production losses, prevalent antimicrobial resistance and substantial impact on livestock- dependent people, there is the need for effective control via vaccination. Protecting the live-attenuated, heat-labile CBPP vaccines against inactivation under elevated temperature especially in tropical Africa becomes pertinent.

Four thermo-stabilisers, namely skim milk (A), trehalose dihydrate (B), skim milk plus sucrose (C), and casein plus sucrose plus sodium glutamate (D) were used to produce vaccine with the T1/44 strain of CBPP causal bacterium. Four batches of vaccines per type of stabiliser were prepared and freeze dried. The thermo-stability and potency of vaccines produced were evaluated using accelerated stability test at different temperatures and for different duration of exposure. The bacterial titre was calculated and expressed in colony forming unit. Results obtained revealed that skim milk plus sucrose (C) and trehalose dihydrate (B) were the most effective thermostabilisers, recording minimum decline in titre along the 14 days of study compared to stabilisers A and D which showed rapid decline trend in titre.

Keywords

Stabiliser, Contagious Bovine Pleupneumonia vaccine, Thermo-stability, Viable count

Introduction

The World Organization for Animal Health has classified contagious bovine pleuropneumonia (CBPP) as a notifiable respiratory illness in cattle. The disease condition, also known as cattle lung disease, is caused by the bacterium Mycoplasma mycoides subsp. mycoides (Mmm), [1] and is characterized by severe fibrinous bronchopneumonia and pleural effusion during the acute to subacute phases, as well as pulmonary sequestration in chronic cases [2]. CBPP is prevalent in Sub-Saharan Africa and is responsible for significant production losses because of high mortality and morbidity rates, as well as the potential for fast expansion. The illness has a substantial impact on livestock-dependent people, resulting in diminished food supplies and significant revenue losses due to trade restrictions [3]. CBPP is said to be one of the most commercially significant cattle diseases in Africa. Despite being eliminated in most areas of the world, Mycoplasma mycoides subsp. mycoides, the causative agent of contagious bovine pleuropneumonia (CBPP), continues to afflict Sub-Saharan Africa, impacting at least 25 nations [4]. Its control consumes the majority of the time and resources of veterinary services. Although numerous control techniques such as vaccination, quarantine, movement restriction, and stamping out have been implemented, vaccination is the only viable control strategy in Africa [5].

Many CBPP vaccines have been developed, but the most often utilised are the attenuated Mmm strains. The T1/44 and T1sr are the current strains utilised for CBPP vaccination, while the T1/44 strain is the most common on the African continent [6]. Vaccination is the primary focus of infection control due to rising resistance of the causal agent to antimicrobial medication. Most vaccines have low thermo-stability; they must be stored at 2-8°C continuously from the time the vaccine is manufactured until it is delivered to a patient. The development of vaccines that are stable over long periods of time will not only lessen their price burden, but will also increase their accessibility to isolated locations all over the world [7]. Protecting the heat-labile CBPP vaccine with a suitable thermo-stabiliser will go a long way in this direction, alleviating the negative impact on livestock-dependent people of Sub-Saharan Africa.

Materials and Methods

Bacterial culture

Freeze dried Mycoplasma mycoides subsp. mycoides vaccine seed strain T1/44 from the African Union Pan African Veterinary Vaccine Centre (AU-PANVAC) was reconstituted and inoculated into Gourlay's Phosphate buffered inoculum medium at a seed ratio of 2%. Inoculated medium was then incubated at 37°C until sufficient mycoplasma growth (72h) was obtained as judged by visual examination of culture turbidity and pH measurement.

The inoculum was tested for sterility and then used to prepare bulk vaccine culture by infecting F66 CBPP Phosphate buffered production medium at a ratio of one-part inoculum to 9 parts medium. Inoculated bulk culture medium were incubated at 37 °C for 48 hours.

Preparation of stabilisers

Four (4) stabilisers consisting of proteins or polysaccharides or both with the following formula were prepared and used in production of CBPP T1/44 vaccines strain based on AU-PANVAC SOPs: 8% sterile skimmed milk suspension (A), 50% trehalose (B), 7% sucrose +7.5% skimmed milk (C) and, 2.5% enzymatic digest casein + 5% sucrose + 1% sodium glutamate (D).

Formulation and freeze-drying

To make the final bulks, bacterial vaccine bulk cultures prepared were mixed with the same volumes (1:1) of the prepared stabilizers separately. Then, 3ml of final bulks were dispensed into sterile vaccine vials. Thereafter, rubber stoppers were loosely applied to filled vials that were then loaded onto the shelves of a freeze-dryer ready for lyophilisation. At the end of lyophilisation cycles, vaccine vials were sealed under vacuum, labelled and stored at -20 °C until use.

Mycoplasma titration

Samples of each type of wet and lyophilised vaccines were collected and titrated for viable counts before and after freeze-drying, using AU-PANVAC SOPs. Subsequent viable count was performed on the freeze dried vaccines after storage at different temperatures (+4°C, 25°C, 37°C and 45°C) and at different period (0, 3, 7, 10, and 14 days) using accelerated stability study to assess the stability and efficacy of each stabiliser. The stability was determined through a drop in viable bacterial count in the vaccine vial for each formulation. After exposing the vaccine vials at different temperatures, reconstitution was done into 2ml phosphate buffered saline prior to implementing viable counts on complete pleuropneumonia like organism (PPLO) media. The titration was performed both in liquid and on solid media. The count of colonies was performed by using inverted microscope (Stemi 305, Zeiss) and the reading of positive wells was performed by using microplate viewer (Titertek®-Viewer machine). The final vaccine titre was determined by calculating the mean of the titres obtained on solid and in liquid media using Spearman Karber formula.

Data analysis

The calculated titres were entered into data extraction sheets created in Microsoft Excel Software (version 2016), from which the curves were drawn in order to evaluate and identify the effective stabiliser(s). Results were summarised using graphs.

Results

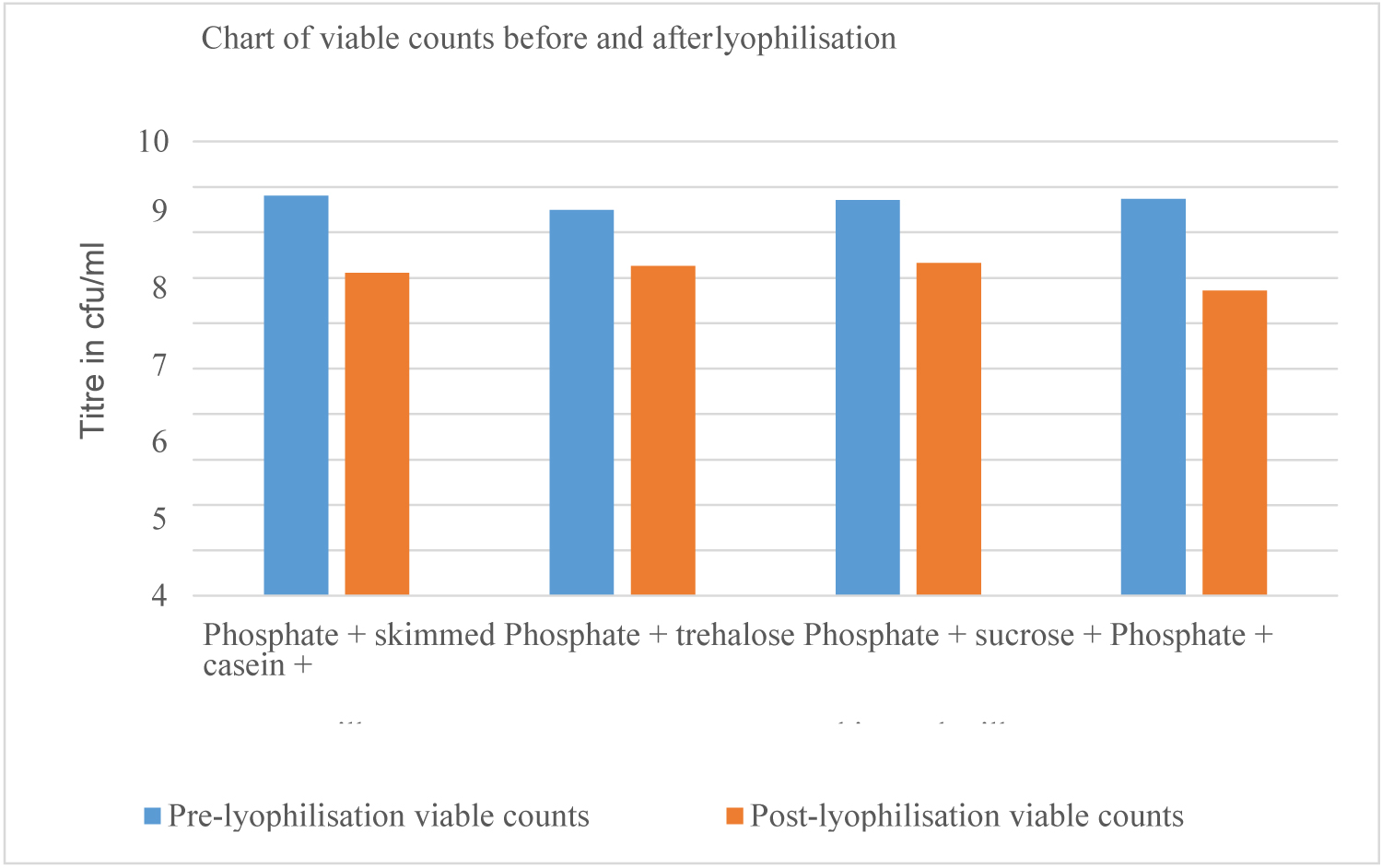

Viable counts in wet vaccines and post-lyophilization

The average viable organisms in wet vaccines for stabiliser A (skimmed milk), B (trehalose), C (skimmed milk plus sucrose), and D (casein plus sucrose plus sodium glutamate) were 108.81cfu.ml-1, 108.49cfu.ml-1, 108.71cfu.ml-1, and 108.74cfu.ml-1 and the average counts immediately after freeze drying were 107.11cfu.ml-1, 107.26cfu.ml-1, 107.33cfu.ml-1, and 106.72cfu.ml-1 respectively. The total average loss in these vaccines during freeze drying process was 101.70 cfu.ml-1 for stabiliser A, 101.23cfu.ml-1 for B, 101.38cfu.ml-1 for C, and 102.02cfu.ml-1 for D as summarised in Figure 1. The highest titre loss due to lyophilisation process was seen with vaccine-based D stabiliser (102.02cfu.ml-1) while the minimum vaccine titre loss against the stabilisers B, C, and A in ascending order were 101.23cfu.ml-1, 101.38cfu.ml-1, 101.70 cfu.ml-1 respectively. However, the stabiliser B was found to be superior as it had the lowest titre loss (101.23cfu.ml-1) among the stabilisers tested seconded by C stabiliser (101.38cfu.ml-1) but the difference in titre loss was not significant as shown in Figure 1.

Viable counts and stability of vaccines with different stabilisers stored at 4 °C

Bacterial titre in vaccines with stabiliser A decreased from 107.11 cfu/mL to 106.86 cfu/mL in 14 days at 4 °C , while vaccines with stabilisers B and C showed a drop in titre from 107.26 cfu/mL to 106.72 cfu/mL and 107.33 cfu/mL to 106.72 cfu/mL respectively. In stabiliser D, titre reduction was from 106.72 cfu/mL to 106.39 cfu/mL within the same period and at similar temperature Figure 2.

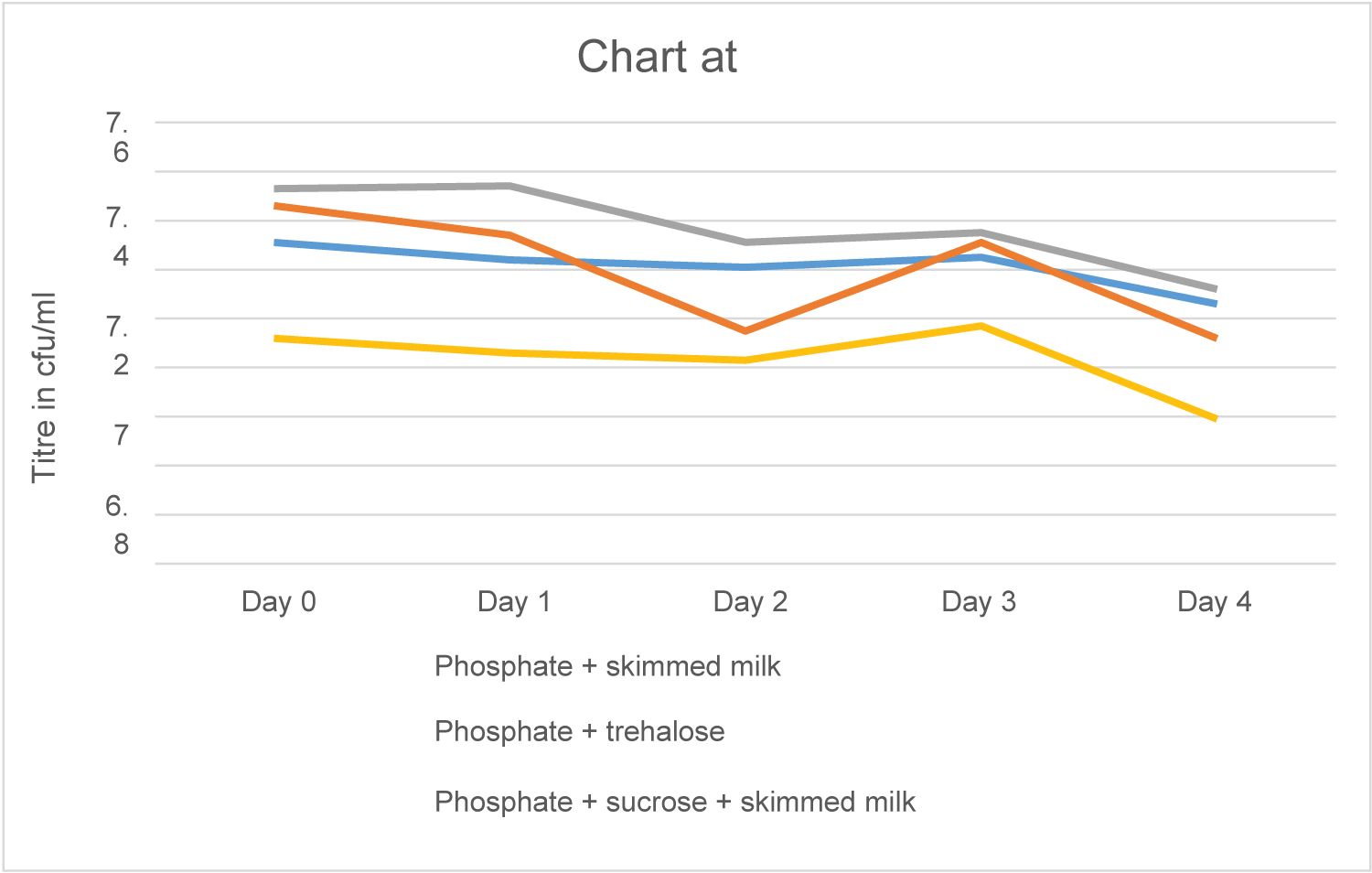

Viable counts and stability of vaccines with different stabilisers stored at 25 °C

At 25 °C (approximate room temperature), vaccines with stabiliser A dropped in titre from 107.11cfu/mL to 103.33cfu/mL in 14 days, while vaccines with stabilisers B and C showed a decrease in titre from 107.26cfu/mL to 103.40cfu/mL and from 107.33cfu/mL to 103.35cfu/mL respectively. At similar temperature and period of storage, vaccines with stabiliser D decreased in titre from 106.72cfu/mL to 103.30cfu/mL Figure 3.

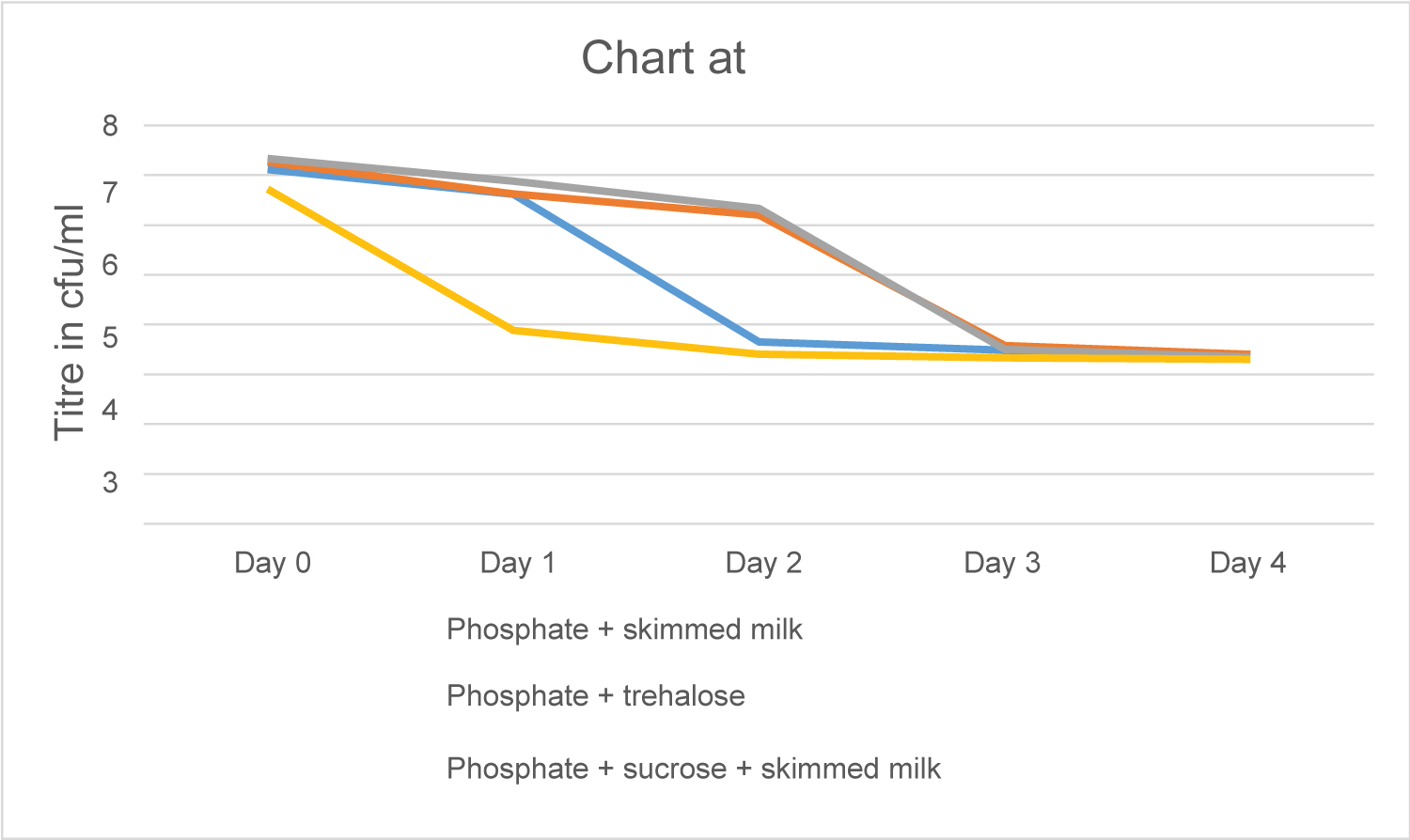

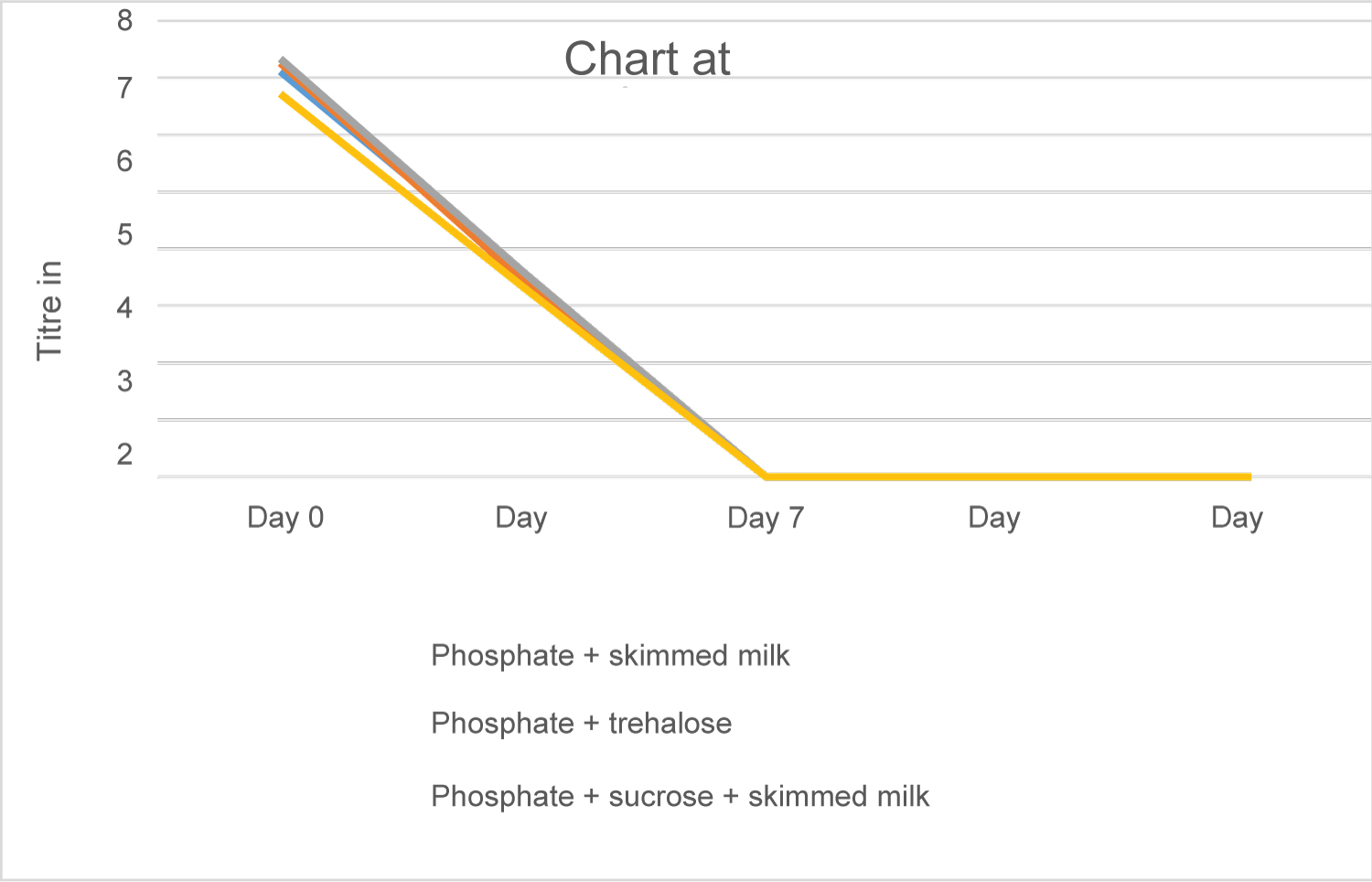

Viable counts and stability of vaccines with different stabilisers stored at 37 °C

Vaccines containing stabilisers A, B, C, and D compounds showed a drop in cfu/ml from 107.11cfu/mL, 107.26cfu/mL, 107.33cfu/mL and 106.72 cfu/mL respectively to 100cfu/mL by day 7 through to day 14. As such, all tested stabilisers could not preserve the vaccine at 37 °C beyond day 3, since a titre of 100cfu/mL was recorded by day 7 Figure 4.

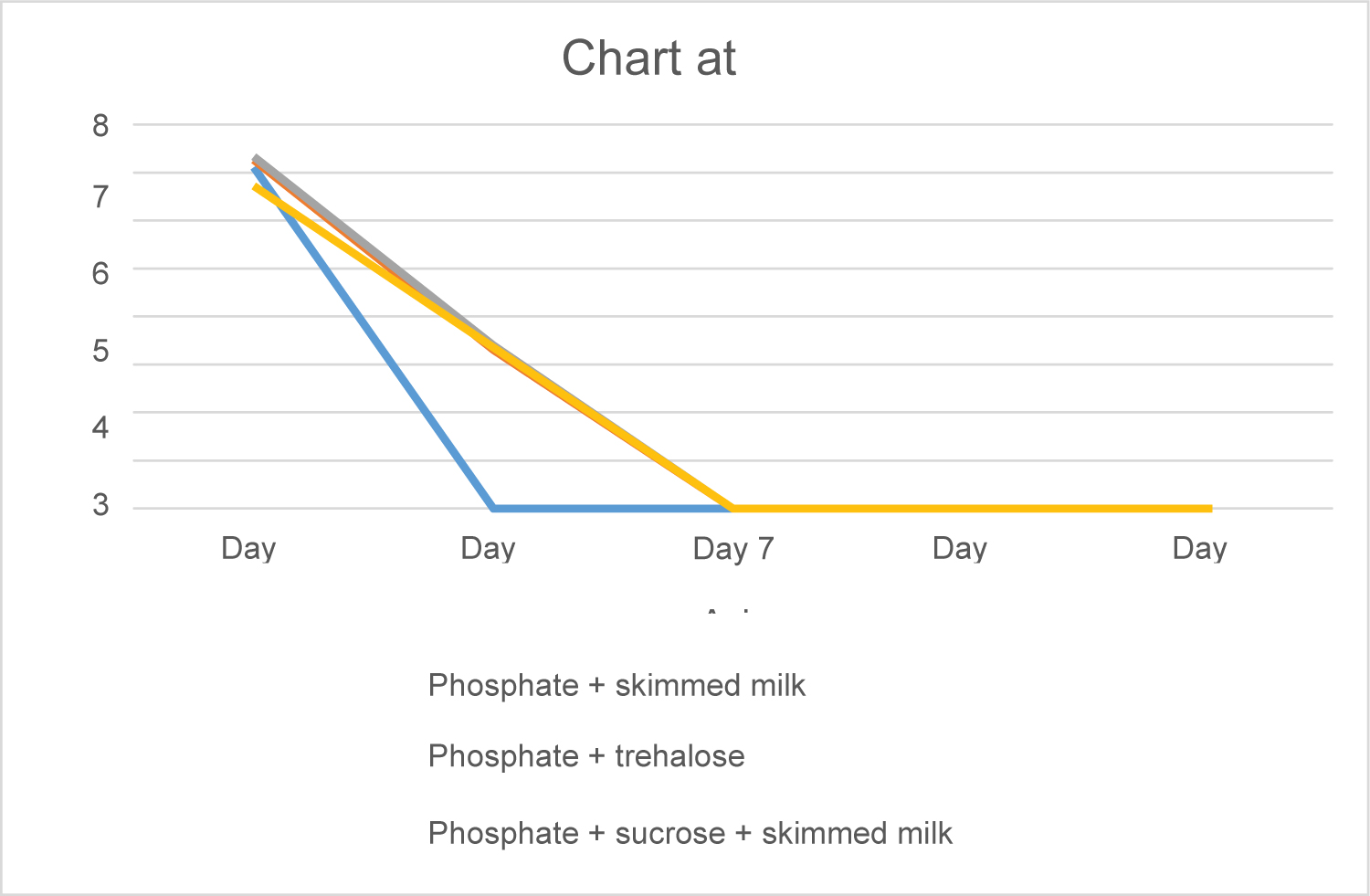

Viable counts and stability of vaccines with different stabilisers stored at 45 °C

Vaccines containing stabilisers A, B, C, and D compounds showed a decrease in titre from107.11cfu/mL, 107.26cfu/mL, 107.33cfu/mL, and 106.72cfu/mL respectively to 100cfu/mL by day 3 for stabiliser A and day 7 for stabilisers B, C and D, indicating the ineffectiveness of stabiliser A to protect the vaccine at 45 °C, and the failure of the other stabilisers to protect the vaccine beyond day 3 at the same temperature Figure 5.

Discussions

Vaccines help protect around three million lives every year, but hundreds of thousands of lives are lost due to the instability of vaccines [7].

Many factors affect stability of vaccines such as, stabilizer, heavy water, process and equipment used in production, lyophilisation process, the cold chain used for maintenance and transportation of vaccines and vials or tubes of vaccines.

Accelerated stability study was conducted, after production of CBPP vaccine batches with different stabilisers, to recommend storage conditions and to establish the shelf life and the potency of vaccine produced.

Results obtained in this study revealed that skim milk plus sucrose (C) and trehalose (B) were found to be superior in providing protection among the stabilisers tested. However, the stabiliser C was the best and most effective that maintains viable mycoplasma along the 14 days of study and showing better uptrend result in titre than stabiliser B. The present outcomes are in agreement with the findings of Physics (2018) that showed stabiliser C as one of the most suitable stabilisers to be used in production of brucella Rev-1 vaccine. Khodadadi (2022) had also reported similar findings, showing the effects of sucrose and skim milk as cryoprotectants in the survival of Lactobacillus rhamnosus GG after 1 week of storage at room conditions.

In contrast, several studies have also been conducted on trehalose based stabiliser showing its ability in maintaining viability of vaccines. It has been demonstrated to protect the infectivity of live-attenuated vaccines for the Peste des petits ruminant (PPR) paramyxovirus, preserve the viability of the live-attenuated mumps virus vaccines based on the RS-12 strain, stabilise the viability of the live vaccine strain of Pasteurella multocida B:3,4 and render the CBPP vaccine more heat tolerant following the xerovac method. Trehalose (B) was found to be superior to two other tested stabilisers [conventional stabiliser (skim milk) (A) and casein plus sucrose plus sodium glutamate (D)] based on results obtained in this present study as it better maintained the viability of CBPP vaccine.

Casein plus sucrose plus sodium glutamate (D) provided insufficient protection and was the least in maintaining viability of CBPP vaccine with brutal loss in titre along the period of study at all storage conditions. This may either be due to the nature of chemicals used or its highest rate of residues of moisture. Anyhow, results showed that increase in moisture content do not reduce the potency of vaccine under the specifications or do not greatly affect potency of vaccine. This is also in agreement with the observation of Hasannia et al., 2015. This finding is contrary to Physics (2018) who showed that casein plus sucrose plus sodium glutamate (D) was the best in maintaining the viability of brucella vaccine 12 months' post-production.

Conclusion

From the outcomes observed in this present study, the vaccines produced using skimmed milk plus sucrose (C) and trehalose dihydrate (B) based stabilizers are the best and most desirable in the formulation of live-attenuated CBPP vaccine since there is no significant difference in vaccine titre loss between these two stabilisers at the end of the period of study (14 days).

At room temperature (20-25 °C), the 2 stabilisers B and C maintained satisfactory result on the viability up to 7 days even if the titres do not meet the OIE recommendations. This lower titre at this temperature may due to the lower titre of vaccine after lyophilisation process. However, exposure to high temperatures (37 and 45°C) affects these vaccines harshly, and is detrimental to their storage over time.

Ultimately, all vaccines especially living bacterial vaccines should be stored at temperatures recommended by national immunization programs and manufacturers.

References

- Thakadu OT, Reetsang NP (2019) Communicating livestock disease risks in Ngamiland: The case of contagious bovine pleuropneumonia. South African Geographical Journal 101: 192-209.

- Di Teodoro G, Marruchella G, Di Provvido A, et al. (2020) Contagious Bovine Pleuropneumonia: A Comprehensive Overview. Veterinary Pathology 57: 476-489.

- Francis MI, Kalang JJ, Raji MA, et al. (2018) Vaccination coverage of contagious bovine pleuropneumonia in Adamawa State, Northeastern Nigeria. Nigerian Veterinary Journal 39: 161.

- Dudek K, Szacawa E, Nicholas RAJ (2021) Recent developments in vaccines for bovine mycoplasmoses caused by mycoplasma bovis and mycoplasma mycoides subsp. Mycoides. Vaccines 9: 1-14.

- Nkando IG (2008) A Comparison of the Stability, Safety and Efficacy of Two Contagious Bovine Pleuropneumonia Vaccine Formulations.

- Safini N, Elmejdoub S, Bamouh Z, et al. (2022) Development and Evaluation of a Combined Contagious Bovine Pleuropneumonia (CBPP) and Lumpy Skin Disease (LSD) Live Vaccine. Viruses 14: 372.

- Dumpa N, Goel K, Guo Y, et al. (2019) Stability of Vaccines. AAPS Pharm Sci Tech 20: 1-11.

- Physics R (2018) 3. Descriptive statistics and data visualization. 21: 1546-1554.

Corresponding Author

Sangdjinan Ndjetel, Pan-African University Life and Earth Science Institute, University of Ibadan, Ibadan, Nigeria

Copyright

© 2022 Sangdjinan N, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.